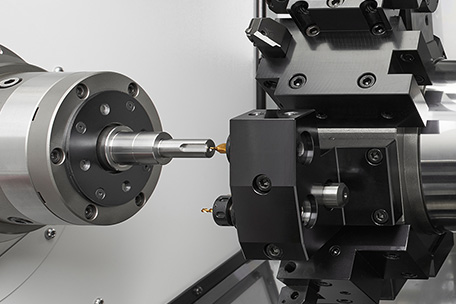

From a humble start 16 years ago, Alcro provides CNC machining and turning of rapid prototype parts and low to mid volume CNC rapid production parts. We use advanced equipment to offer you a variety of CNC machining services including milling and turning. Alternatively, we fabricate precised tooling metal components for all industries. We pride ourselves on first class quality, on time delivery, commitment to work, learning and sharing attitude.

Alcro also specialized in secondary machinery trading based on our strong resources in Phlippine and Singapore.

We gather and creat new relationship in orde to satisfy every customer.

Each customer around the world is God of Alcro, we are looking forward to your copperations!

.png) CNC machining

CNC machining.jpg) Surface treatment

Surface treatment.jpg) Mass production

Mass productionCNC service ranges:We specialized in fabricating Machining parts for steel, Aluminium,copper,Titanium as well as engineering plastics; Tooling service: Connectors, Semiconductors, Molding and Stamping tooling parts.

At Alcro, we believe that early collaboration is the driving force behind product success. By unifying efforts with our customers and alliance partners, a holistic approach to product development is achieved. Our monthly capacity of NC parts is 10000pcs, molding cavity insert 1500pcs, semiconductor DTFS punch and dies 2000pcs.