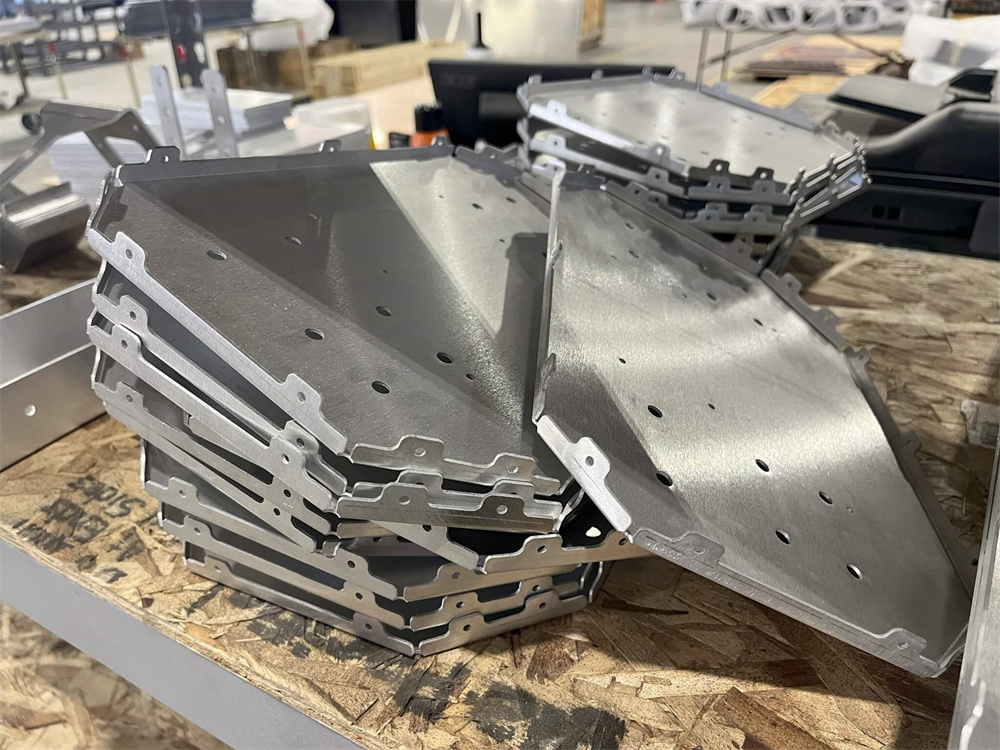

Sheet metal fabrication is one of the most essential manufacturing processes in modern industry. From enclosures for electronics to structural brackets, sheet metal components are found in everything from consumer goods to aerospace systems. Its cost-efficiency, scalability, and adaptability make it a cornerstone of product development across industries.

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the process of forming flat metal sheets into specific shapes or structures using a variety of techniques. It is widely used in industries such as automotive, aerospace, construction, electronics, and manufacturing due to its versatility, strength, and cost-effectiveness.

It involves both subtractive (e.g., laser cutting) and additive (e.g., welding, fastening) processes. Common methods include:

· Cutting:Laser cutting, plasma cutting, waterjet, and punching.

· Bending/Forming:Using press brakes or roll formers to shape parts.

· Joining:Welding, riveting, and using threaded fasteners.

· Finishing:Surface treatments like powder coating or anodizing.

Sheet metal fabrication is widely used in:

· Electronics enclosures

· Vehicle body panels

· HVAC components

· Structural brackets and frames

· Custom machinery housings

The process allows for high-volume production, prototyping, and one-off custom builds with fast turnaround times.

Sheet Metal Fabrication Standards

Designing sheet metal parts requires knowledge of established engineering standards. They are essential guidelines that ensure consistency, safety, quality, and interoperability of fabricated parts across industries. These standards cover material specifications, design practices, tolerances, testing methods, and safety procedures.

Key Standards Bodies

· ISO (International Organization for Standardization)

ISO 2768: General tolerances for linear and angular dimensions

ISO 9001: Quality management systems

· ASME (American Society of Mechanical Engineers)

ASME Y14.5: Dimensioning and Tolerancing (GD&T)

· DIN (Deutsches Institut für Normung)

DIN EN 10130: Cold-rolled low carbon steel for deep drawing

· RoHS & REACH

Regulatory standards for material compliance in electronics and consumer goods

Tolerance Considerations

Tolerances in sheet metal are generally looser than in CNC machining:

Feature | Typical Tolerance |

| Bend angle | ±1° |

Bend radius | ±0.25 mm |

Hole diamete | ±0.1 mm |

Part outline accurac | ±0.2 mm |

Proper GD&T usage helps communicate functional requirements without over-constraining the part, which can increase cost.

Design Guidelines

Effective sheet metal design is crucial for manufacturability, cost-efficiency, and functional performance. Below are key guidelines and best practices used by engineers and fabricators.

Thickness Guidelines

· Standard sheet thickness: 0.5 mm – 6 mm

· Use uniform thickness throughout a design to reduce cost and complexity.

· Consider material bendability (e.g., aluminum bends more easily than stainless steel).

Bending Rules

· Minimum Bend Radius: Typically 1× sheet thickness for most materials (check specific alloy requirements).

· Bend Relief: Add relief cuts near bends to avoid tearing in tight corners: Slot length ≥ material thickness; Slot width ≥ bend radius.

· Bend Orientation: Orient all bends in the same direction when possible to reduce setup time.

· Avoid placing holes too close to bends; use this rule: Distance from hole to bend edge ≥ 2× sheet thickness + bend radius.

Minimum Bend Radius

The bend radius should match or exceed the material thickness to avoid cracking. General guideline:

· Bend radius ≥ 1× material thickness

For example, a 1.5 mm thick aluminum sheet should have a bend radius of at least 1.5 mm.

Hole and Feature Placement

· Holes near bends should be spaced at least 2× the material thickness away.

· Avoid placing slots or cutouts along the bend line.

· Maintain a minimum hole diameter of 1.5× material thickness.

K-Factor and Bend Allowance

Bending stretches the outer material and compresses the inner material. The K-Factor (typically 0.3 to 0.5) helps calculate bend allowances. Use accurate K-Factor values in your CAD software to prevent part deformation.

Tabs and Notches

· Keep notches at least 3× material thickness deep.

· Tabs should be longer than they are wide and evenly spaced.

Avoid Complex Geometry

Simpler designs reduce tooling costs. Use:

· Straight bends over curves

· Fewer cutouts or embossed features

· Flat faces when possible for better clamp fit

Example Design Rules Summary

| Feature | Rule of Thumb |

| Minimum bend radius | ≥ 1× thickness |

| Minimum hole size | ≥ 1.5× thickness |

| Distance hole to edge | ≥ 2× thickness |

| Threading in sheet | Use self-clinching nuts/studs or weld nuts |

| Notch/tab length | ≤ 5× thickness (to avoid warping) |

Materials and Finishes

The performance, durability, and appearance of a sheet metal part heavily depend on the material and surface finish chosen. Selecting the right combination ensures that parts meet both functional and aesthetic requirements.

Common Sheet Metals

Mild Steel

· Pros: Strong, cost-effective, easy to weld and machine

· Cons: Prone to corrosion without finishing

· Common Grades: ASTM A36, A1008, A1011

· Applications: Frames, brackets, structural parts

Stainless Steel

· Pros: Corrosion-resistant, durable, good strength

· Cons: Higher cost, harder to cut/form

· Common Grades: 304, 316

· Applications: Food equipment, medical devices, outdoor enclosures

Aluminum

· Pros: Lightweight, corrosion-resistant, easy to machine

· Cons: Softer, less strong than steel

· Common Grades: 5052, 6061

· Applications: Aerospace, electronics, automotive panels

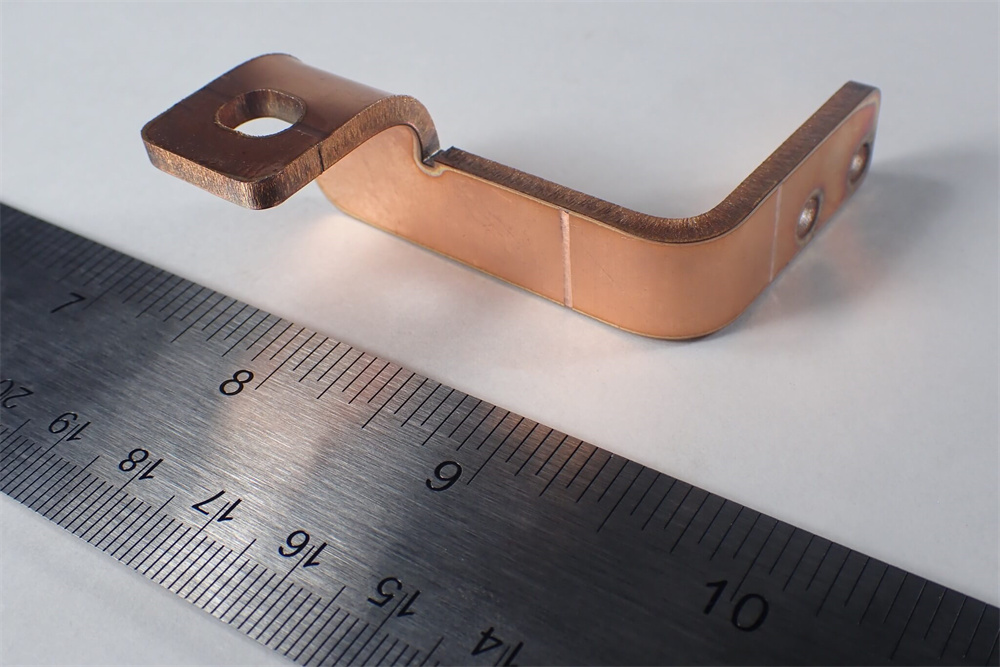

Copper

· Pros: Excellent electrical/thermal conductivity, antimicrobial

· Cons: Expensive, soft, oxidizes quickly

· Applications: Electrical components, heat sinks

Brass

· Pros: Decorative, corrosion-resistant, easy to machine

· Cons: Costly compared to steel

· Applications: Hardware, trim, plumbing

Finishing Options

Finishing enhances corrosion resistance, aesthetics, and wear properties. Choose finishes based on the product’s environment and usage conditions.

Protective Finishes

| Finish | Description | Suitable Materials | Notes |

| Powder Coating | Dry powder baked onto surface, durable, colored | Steel, aluminum | Tough and weather-resistant |

| Anodizing | Electrochemical oxide layer | Aluminum | Corrosion resistance + color options |

| Galvanizing | Zinc coating applied via dipping or electroplating | Steel | Great for outdoor applications |

| Electropolishing | Smooths & passivates metal surface | Stainless steel | Improves hygiene and corrosion resistance |

Aesthetic Finishes

| Finish | Description | Notes |

| Brushed | Linear, matte surface with visible grain | Common on stainless and aluminum |

| Polished | Shiny, reflective surface | Often used on decorative or visible parts |

| Bead Blasting | Uniform matte texture | Removes defects, improves paint adhesion |

Functional Finishes

| Finish | Function | Notes |

| Black Oxide | Adds mild corrosion resistance | Low cost, used on steel |

| Zinc Plating | Electroplated zinc layer | Corrosion-resistant, conductive |

| Passivation | Removes contaminants on stainless steel | Enhances corrosion resistance |

Choosing the Right Combination

| Criteria | Best Choices |

| Corrosion Resistance | Stainless steel, anodized aluminum |

| Lightweight | Aluminum, thin-gauge steel |

| Cost Efficiency | Mild steel + powder coating |

| Electrical Use | Copper, tin-plated materials |

| Aesthetic Finish | Brushed stainless, polished aluminum |

Steps to Prepare & Source Your Custom Parts

Successfully sourcing custom sheet metal parts requires careful planning, clear documentation, and effective communication with your fabricator. Here's a step-by-step guide to help you move from concept to production smoothly.

Define the Requirements

Start by clearly specifying what the part needs to do:

· Function: Structural support? Enclosure? Aesthetic cover?

· Environment: Indoors, outdoors, high humidity, temperature extremes?

· Mechanical needs: Load-bearing, vibration resistance, precision fit?

Tip: The more details you provide, the fewer revisions and delays you’ll face.

Create a Manufacturable Design

Design your part using CAD software with sheet metal-specific tools (e.g., SolidWorks, Fusion 360, AutoCAD).

Key considerations:

· Choose standard material thicknesses (e.g., 1.5 mm, 2 mm, 3 mm)

· Use consistent bend radii and avoid tight bends near cutouts

· Include:

Bend lines

Hole dimensions

Flat pattern drawings if possible

Tip: Overly tight tolerances or unnecessary complexity unless absolutely needed.

Prepare Detailed Drawings and Files

Your documentation package should include:

| File Type | Purpose |

| 2D Drawing (PDF, DWG) | Shows dimensions, tolerances, notes |

| 3D Model (STEP, IGES) | Used for CNC and laser programming |

| Flat Pattern (DXF) | Required for laser/plasma cutting |

| BOM (Bill of Materials) | Lists materials, fasteners, finishes |

Tip: Include callouts for material type, finish, quantity, and critical tolerances.

Select the Right Supplier

Choose a supplier that matches your needs in:

· Capabilities (laser cutting, bending, welding, coating)

· Experience (industry-specific knowledge)

· Certifications (ISO 9001, AWS, RoHS, etc.)

· Lead Time & MOQs (minimum order quantities)

Sources:

· Local shops for fast turnaround

· Online platforms with brand effect

· Overseas suppliers have cost-effectiveness advantages

Request a Quote

Submit your design package with:

· Quantity

· Material preference

· Finish type

· Required delivery date

· Any certifications or inspection requirements

Tip: Get multiple quotes for price comparison and capacity checks.

Review DFM Feedback (If Provided)

Some fabricators will offer Design for Manufacturability (DFM) suggestions:

· Modifying tight bends

· Suggesting alternate fasteners

· Recommending stock material sizes

Take this seriously—it can reduce cost, lead time, and risk.

Approve Prototype or First Article (If Applicable)

For complex or high-volume projects:

· Ask for a First Article Inspection (FAI) part

· Test fit and function before full production

· Make any final revisions

Proceed to Production and Delivery

Once you approve the prototype or quote:

· Submit purchase order

· Confirm lead time and shipping method

· Track progress and communicate frequently with your supplier

Inspect and Verify Upon Delivery

When you receive parts:

· Inspect dimensions and surface finish

· Test fit and function

· Review accompanying documents (CoC, test reports, etc.)

If issues arise, work with the supplier quickly on rework or replacement.

Suggestions to Reduce the Machining Cost

Reducing machining costs—especially for sheet metal fabrication—requires a blend of smart design, material choices, and manufacturing awareness. Here’s a list of practical, high-impact suggestions to reduce cost without compromising quality.

Optimize Part Geometry

· Reduce the number of bends.

· Avoid tight bend radii and complex contours.

· Combine parts where possible.

Standardize Features

· Use common hole sizes.

· Maintain consistent material thickness across parts.

· Avoid custom tooling (embosses, lances) unless necessary.

Choose Cost-Effective Materials

· Use aluminum instead of stainless steel when corrosion resistance is not critical.

· Consider cold-rolled steel with powder coating for strength and affordability.

Avoid Over-Engineering

· Design for functionality, not aesthetics alone.

· Overly tight tolerances or unnecessary finishing will drive up costs.

Batch Production

· Ordering in larger volumes reduces per-part setup and handling time.

· Group similar parts together to minimize sheet waste.

Collaborate with Manufacturers

· Ask for Design for Manufacturing (DFM) feedback.

· Involve fabricators early in the design process to identify cost-saving opportunities.

Sheet metal fabrication is a versatile and powerful manufacturing process, but getting it right depends on thoughtful design and practical material choices. By adhering to industry standards, optimizing part geometry, and working closely with suppliers, engineers and designers can produce high-quality parts at competitive costs.

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

8 min readPublished Dec 08 2025

8 min readPublished Dec 08 2025

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.