When it comes to motorsports, every second counts—literally. Whether it’s on the racetrack or in the garage, teams are constantly looking for ways to speed up processes without compromising on performance or safety. This is where CNC machining comes into play. CNC machining has revolutionized industries by providing faster, more accurate, and cost-effective manufacturing solutions. In motorsports, the precision and efficiency of CNC machining can mean the difference between crossing the finish line first and falling behind. But how exactly can this CNC machining technology favor motorsports industry? Let’s dive in.

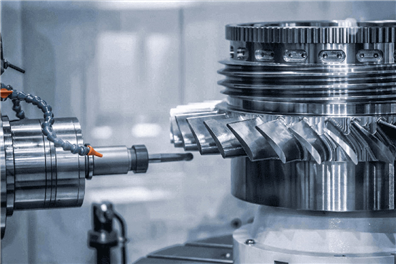

CNC machining is a computerized manufacturing process that controls machine tools like lathes, mills, routers, and grinders through software. Instead of manual labor, CNC systems follow programmed instructions to create precise, intricate parts with minimal human intervention.

How it begins to use CNC machining? The process starts with a 3D design created on CAD (Computer-Aided Design) software. That design is then converted into machine instructions (G-code), which tells the CNC machine exactly how to cut, shape, or drill raw material into a finished component. Every movement is planned out to within microns of accuracy.

Speed vs. Accuracy: Finding the Balance

Motorsport is exhilarating, because it’s not just about going fast—there’s a delicate balance between speed and precision that determines whether you’ll end up on the podium or in the pits. Fans cheer for breathtaking speeds, but the true art of racing lies in finding that sweet spot where you’re not just quick, but also accurate.

Besides, motorsport has always been the ultimate test of human and machine. The intoxicating blend of roaring engines, burning rubber, and split-second decisions make it one of the most thrilling spectacles on Earth. But what most fans don’t realize is that speed alone doesn’t win races. While it’s exhilarating to fly down a straightaway, it’s accuracy that truly defines a driver’s mastery. Without precision, speed becomes reckless. The real challenge is mastering both.

In motorsports, there’s a constant tug-of-war between speed and precision. A tiny misalignment or error in a part can lead to catastrophic consequences during a race. CNC machining ensures that every part is manufactured with pinpoint accuracy, allowing teams to focus more on speed and performance without worrying about component failure.

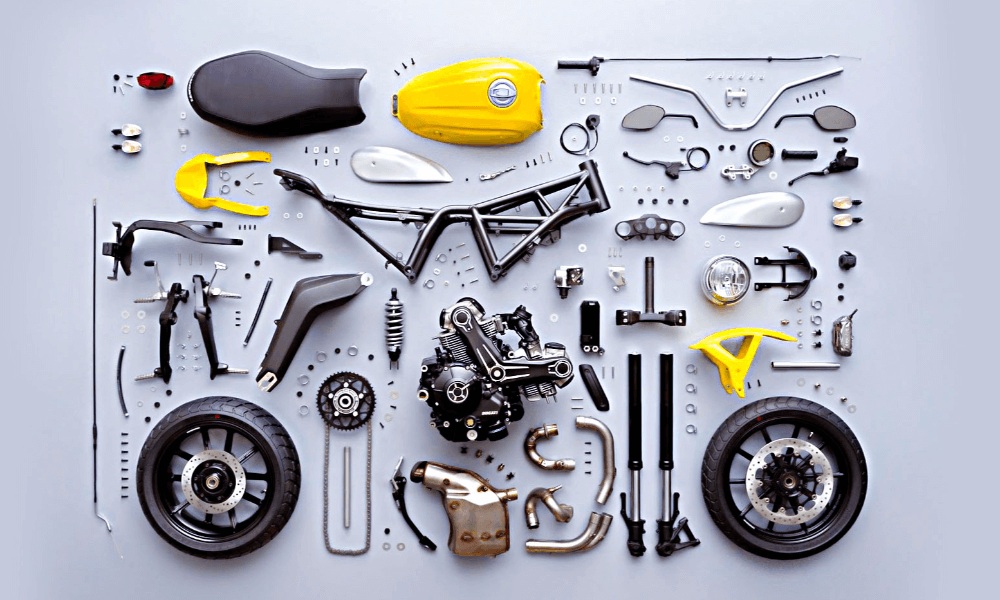

Whether it’s a custom suspension system, brake calipers, or aerodynamic components, CNC machining delivers flawless parts that fit perfectly every time. This eliminates the need for trial and error, saving valuable time in preparation for race day.

Considering above, CNC machining is a manufacturing technology that is controlled by a computer. In contrast to traditional manual machining, CNC machining controls the movement of tools through pre-programmed digital commands that enable precise cutting, drilling and milling of materials. This technology allows the manufacturing process to minimize human error and ensure accuracy and consistency of each part, especially in the production of parts with complex geometries and tight tolerance requirements. CNC technology offers the following advantages over traditional manual machining:

High Accuracy: CNC machining is capable of operating in the micron level of accuracy, resulting in a dramatic increase in consistency and precision in the production of parts.

Automation: Once a program has been set up, CNC machines can run automatically, reducing the amount of time spent on manual operations.

Multi-axis machining: CNC machines can speed up production by operating on multiple axes at the same time, thus completing multiple steps at once.

How CNC Machining Reduces Time in Motorsports

Time is money, especially in motorsports. CNC machining allows teams to quickly prototype parts without waiting weeks for manual production or outsourcing to third-party manufacturers. This rapid turnaround means teams can test, modify, and perfect components in a fraction of the usual time.

With the ability to quickly produce or replace broken parts, CNC machining helps minimize downtime. If a part breaks during practice or testing, it can be replaced in hours, not days, keeping vehicles running smoothly and reducing delays.

One of the most significant ways CNC machining saves money is by reducing the need for manual labor. Automated machines can work around the clock with minimal oversight, lowering labor costs and freeing up skilled technicians to focus on more complex tasks.

Besides, CNC machines are incredibly efficient in using materials, reducing waste. By cutting with high precision, these machines minimize excess material removal, which translates into cost savings—especially when working with expensive metals and composites.

Time management is a critical aspect of the motorcycle tuning process, especially when racing is tight. the efficiency of CNC machining directly addresses several key issues in tuning:

Automation and High Accuracy Reduces Rework Time: The high accuracy of CNC machining virtually eliminates errors in manual machining and reduces wasted time in rework or redesign. Once a design has been verified through digital modeling, the part produced will be identical to the design.

Rapid Iteration and Prototyping: When modifying a motorcycle, parts often need to be tested and tweaked multiple times. the rapid response capability of CNC machining allows engineers to prototype multiple different parts in a short period of time, allowing for rapid iteration and shorter development cycles.

Multi-functional machining machine integration: The ability of many CNC machines to integrate multiple machining functions, such as milling, turning and drilling, means that complex parts can be machined in a single pass without the need for multiple clamping and tuning, resulting in significant savings in production time.

Customization and Flexibility

If you’ve ever dreamed of a motorcycle that’s uniquely yours, you’re not alone. Customizing a motorcycle is like creating a piece of art, combining form and function to match your personal tastes and riding needs. Whether it’s for aesthetics, performance, or comfort, custom parts allow riders to transform their two-wheeled machines into something truly special.

The motorcycle modification industry has always been known for its demand for personalization and high performance. As technology advances, riders and engineers want to be able to build motorcycles faster and more accurately to meet their specific needs. Whether it’s to enhance performance, appearance, or prepare a vehicle for the track, CNC machining is becoming an integral part of the tuning process. Through high precision and efficient production methods, CNC machining not only saves time, but also greatly improves the quality and consistency of motorcycle modifications.

Motorsports often requires highly specialized, custom-made parts, and CNC machining makes this process easy. Whether a team needs a unique engine component or a specialized gearbox, CNC machines can create one-off or limited-run parts with the same precision and quality as mass production.

CNC machining also enables engineers to push the boundaries of design. With the ability to work with intricate geometries and complex materials, it supports the creation of innovative parts that were previously impossible to manufacture. This keeps teams ahead of the curve, both in performance and technological advancement.

CNC machined parts are not only precise, but they’re also incredibly durable. By using the highest quality materials and manufacturing techniques, parts are built to withstand the rigors of motorsports, lasting longer than manually produced alternatives. Durable, precision parts enhance vehicle performance. Whether it’s lighter-weight components for improved speed or sturdier parts to handle extreme forces, CNC machining allows for optimization in ways that manual methods simply can’t achieve.

Sustainability might not be the first thing that comes to mind when you think of motorsports, but CNC machining is helping the industry go greener. By using materials more efficiently and reducing waste, it contributes to more sustainable manufacturing practices. CNC machines are designed to operate efficiently, consuming less energy than traditional manufacturing methods. This not only helps motorsports teams save money on energy costs, but it also reduces their environmental footprint.

CNC machining is not just another tool in the motorsports industry, it’s a game-changer. From reducing production time to cutting costs and improving performance, this technology is key to staying competitive. The future of motorsports will likely rely even more on CNC machining as teams continue to seek ways to fine-tune their processes and gain that winning edge. Whether it’s creating prototypes faster or producing custom parts with precision, CNC machining is an investment that pays for itself in speed, passion and performance.

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

6 min readPublished Dec 22 2025

6 min readPublished Dec 22 2025

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.