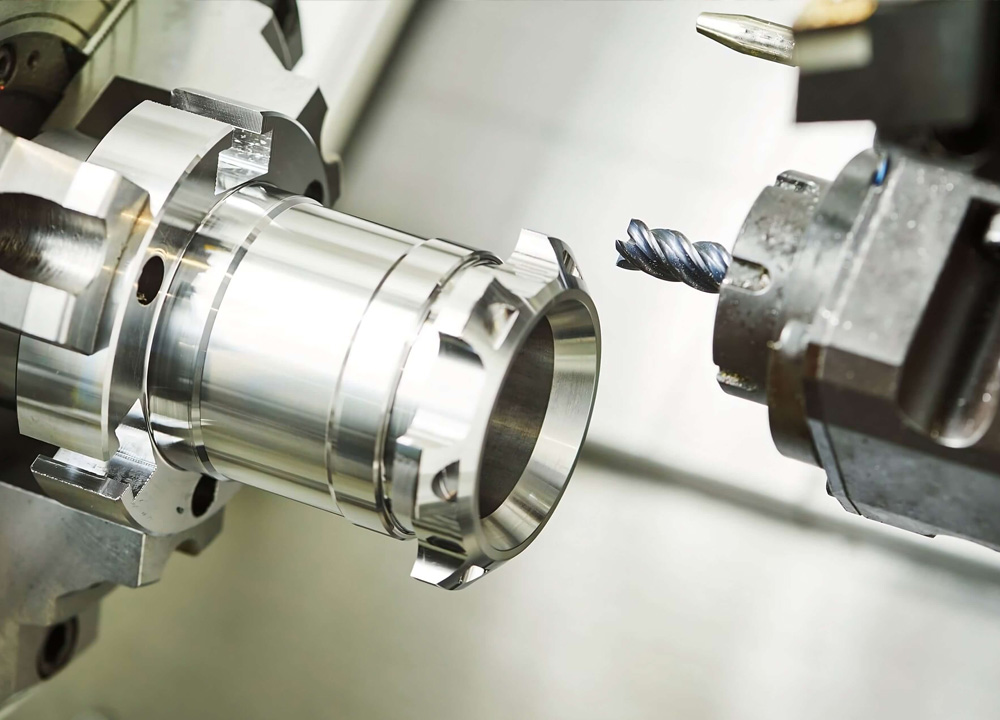

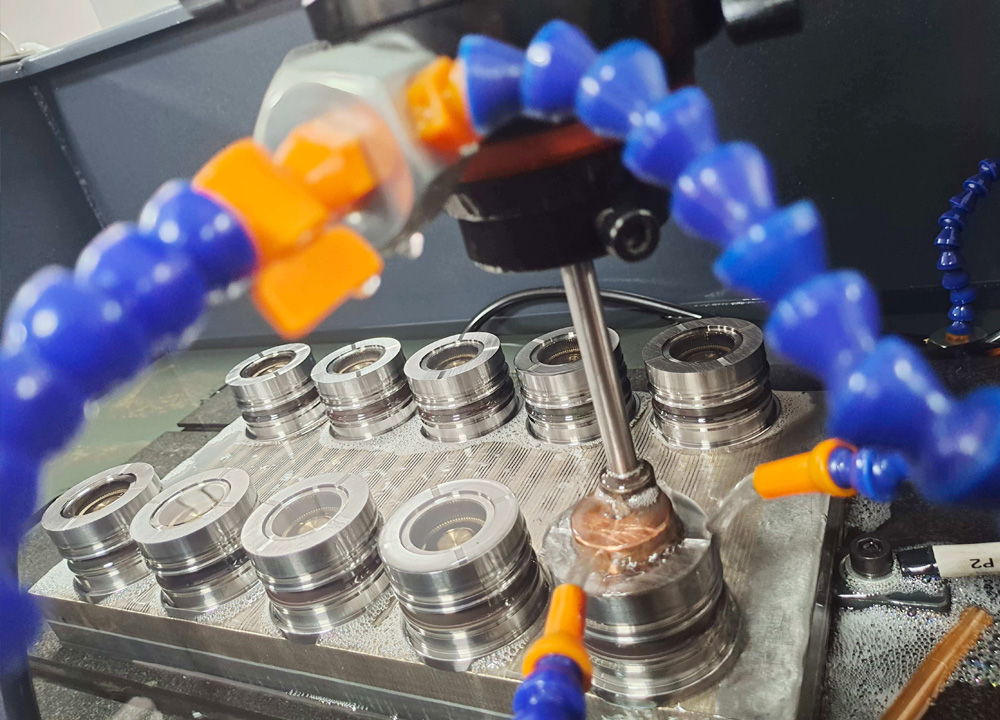

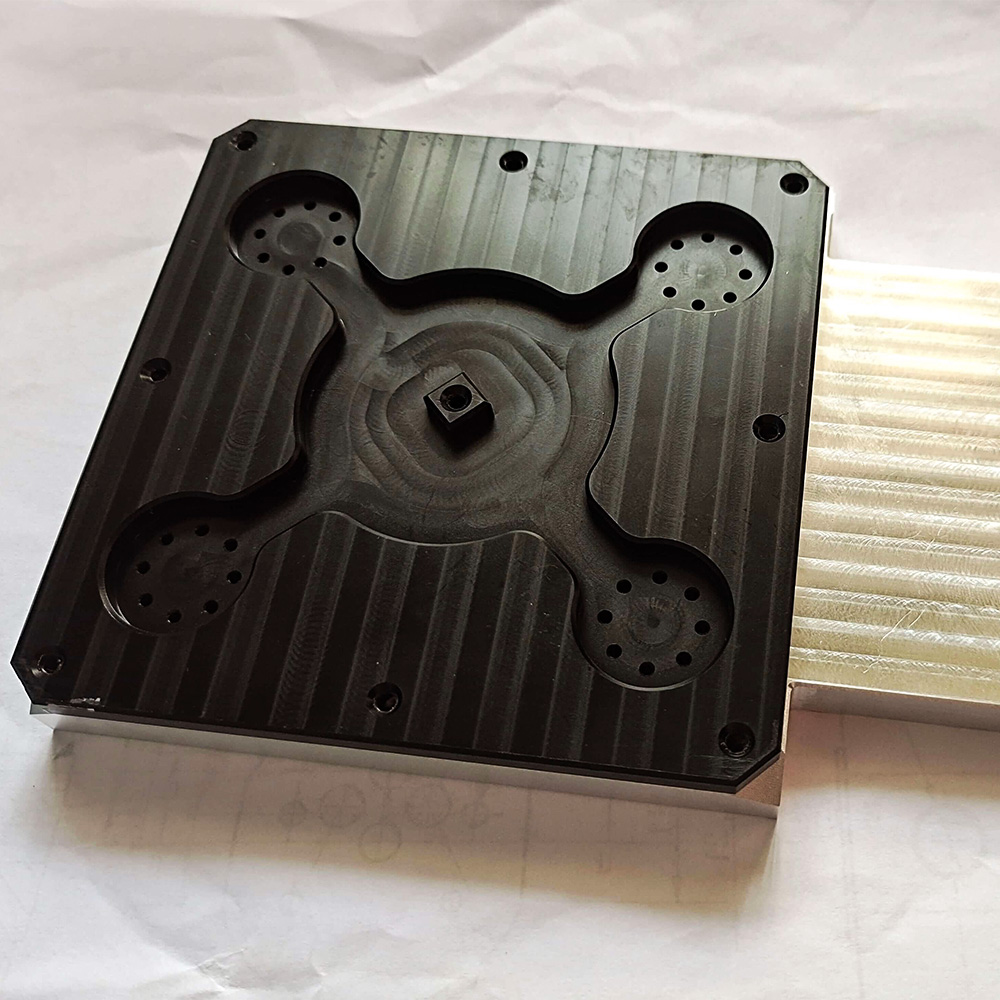

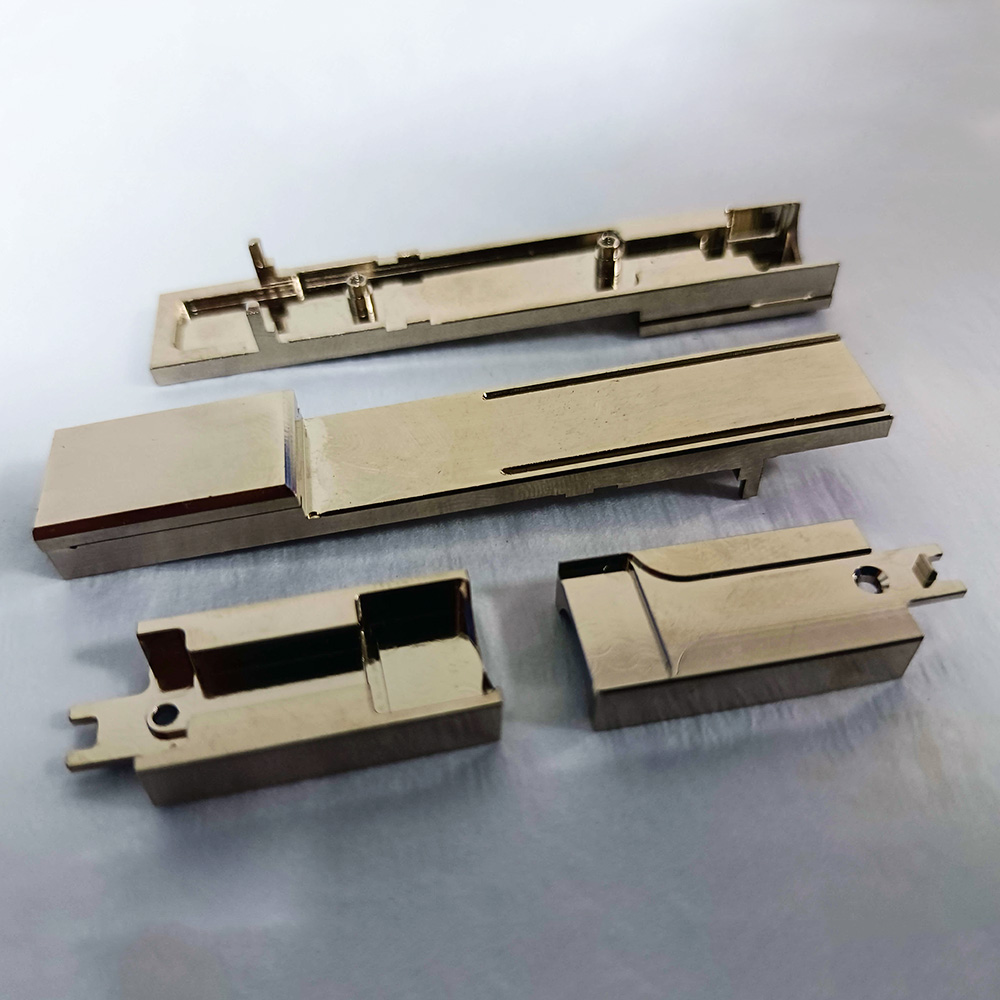

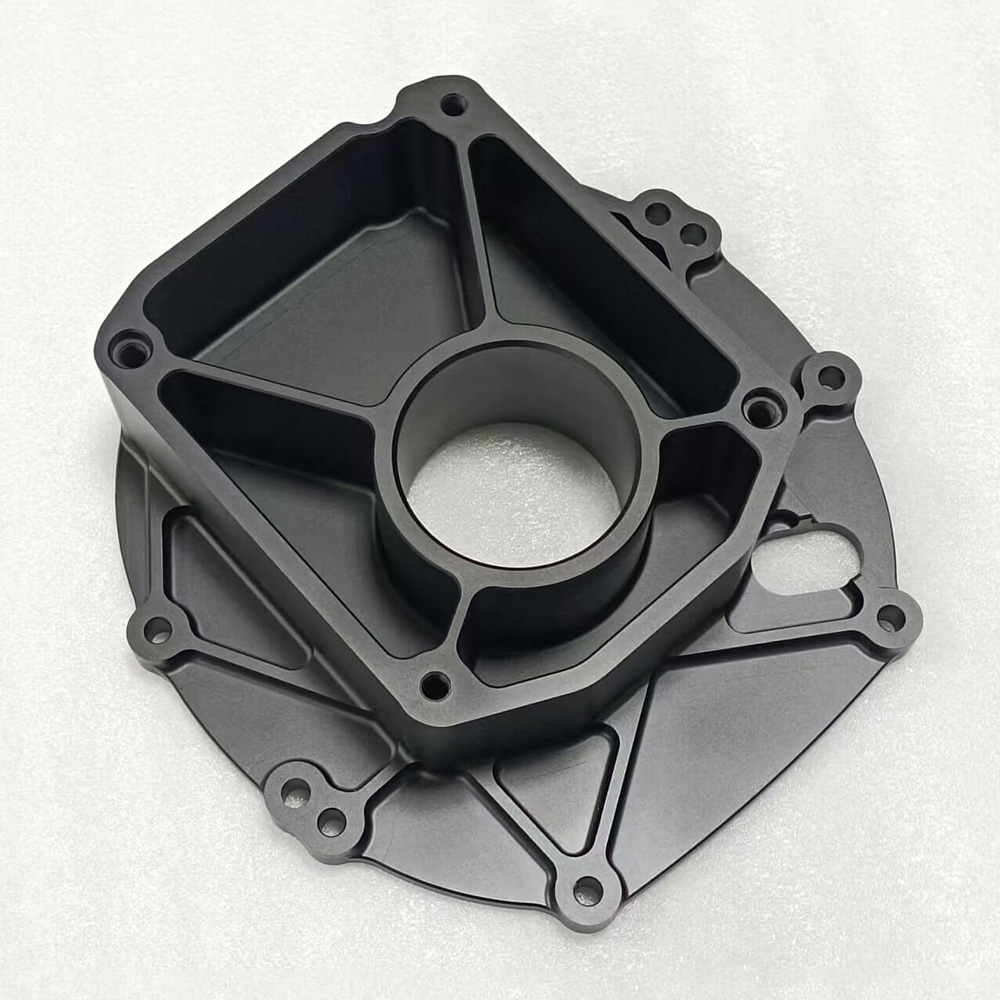

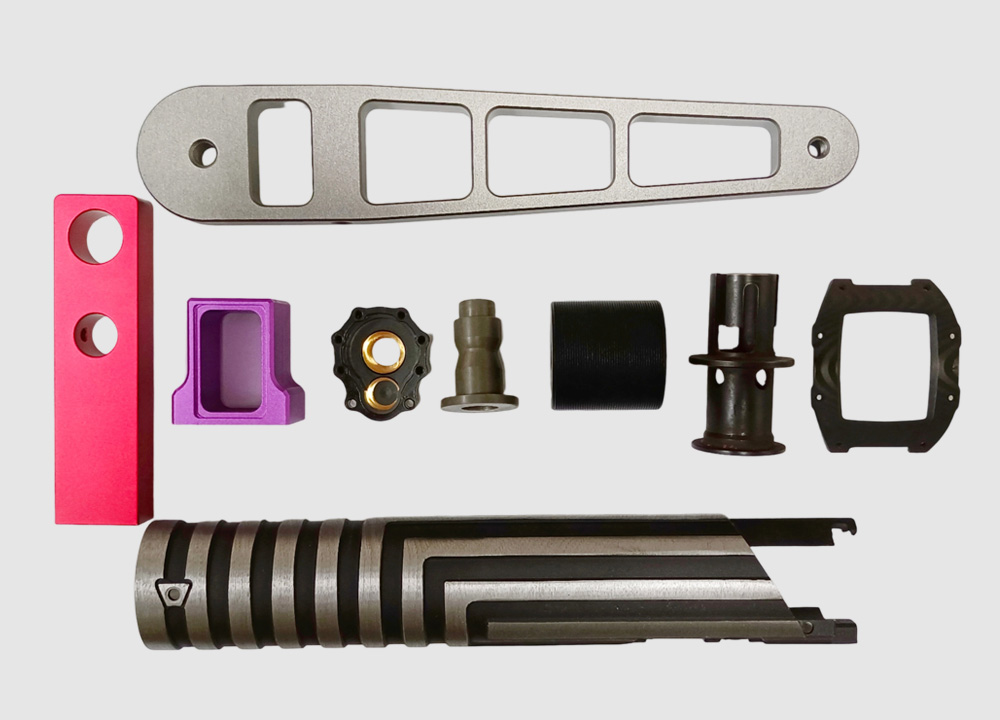

Prototype machining is a vital step in the product development process, allowing engineers and designers to create physical, functional parts quickly and accurately for design verification, engineering testing and iteration before mass production.

Accelerate development cycles

Accelerate development cycles

Reduce risk of downstream manufacturing errors

Reduce risk of downstream manufacturing errors

Improve product quality through early real-world testing

Improve product quality through early real-world testing

Save cost by catching design issues before tooling

Save cost by catching design issues before tooling

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

All Uploads Are Secure and Confidential

All Uploads Are Secure and Confidential

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.