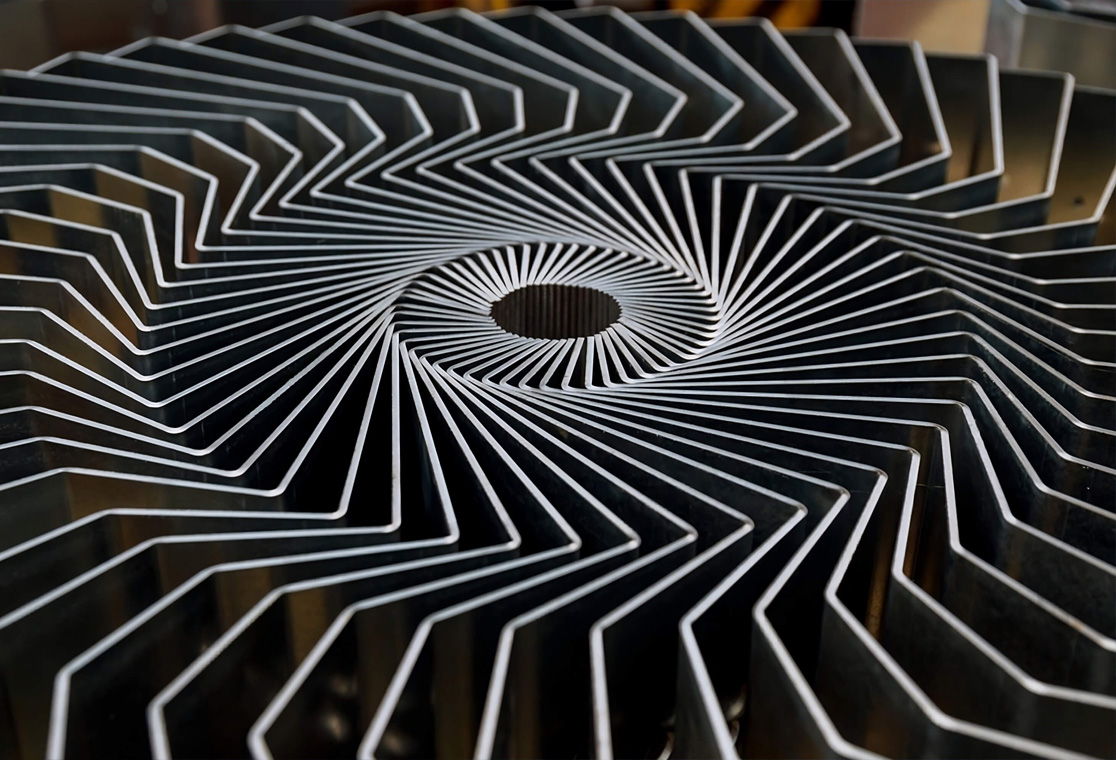

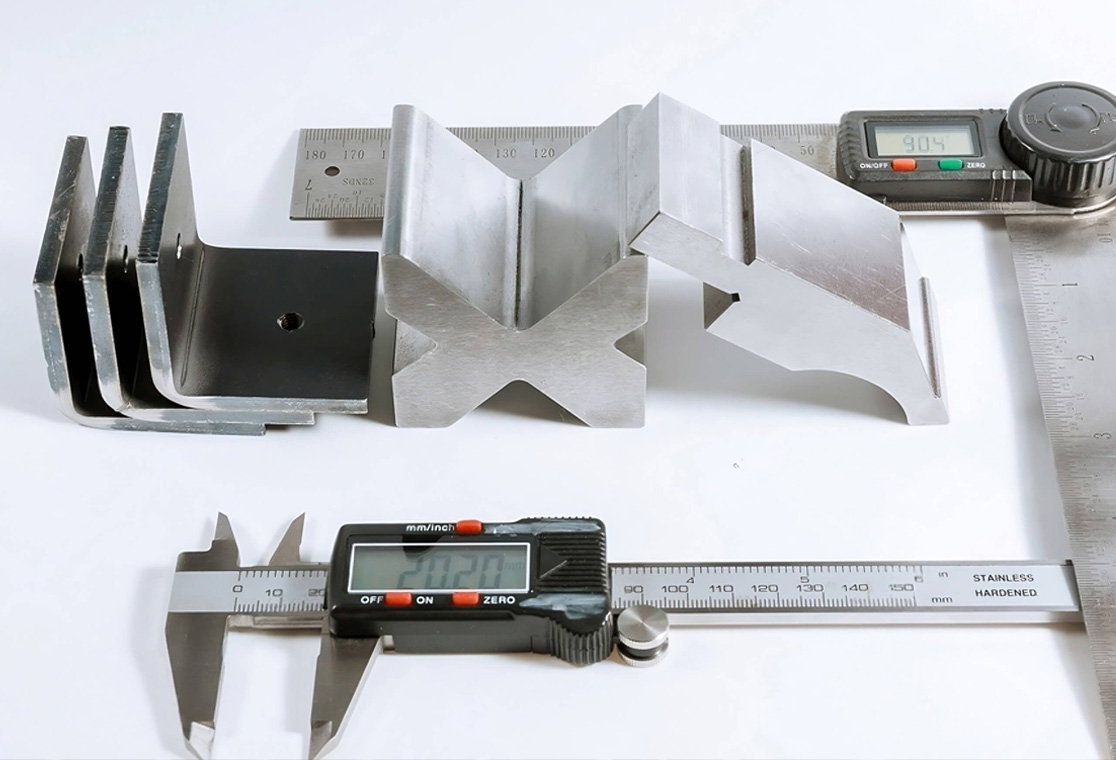

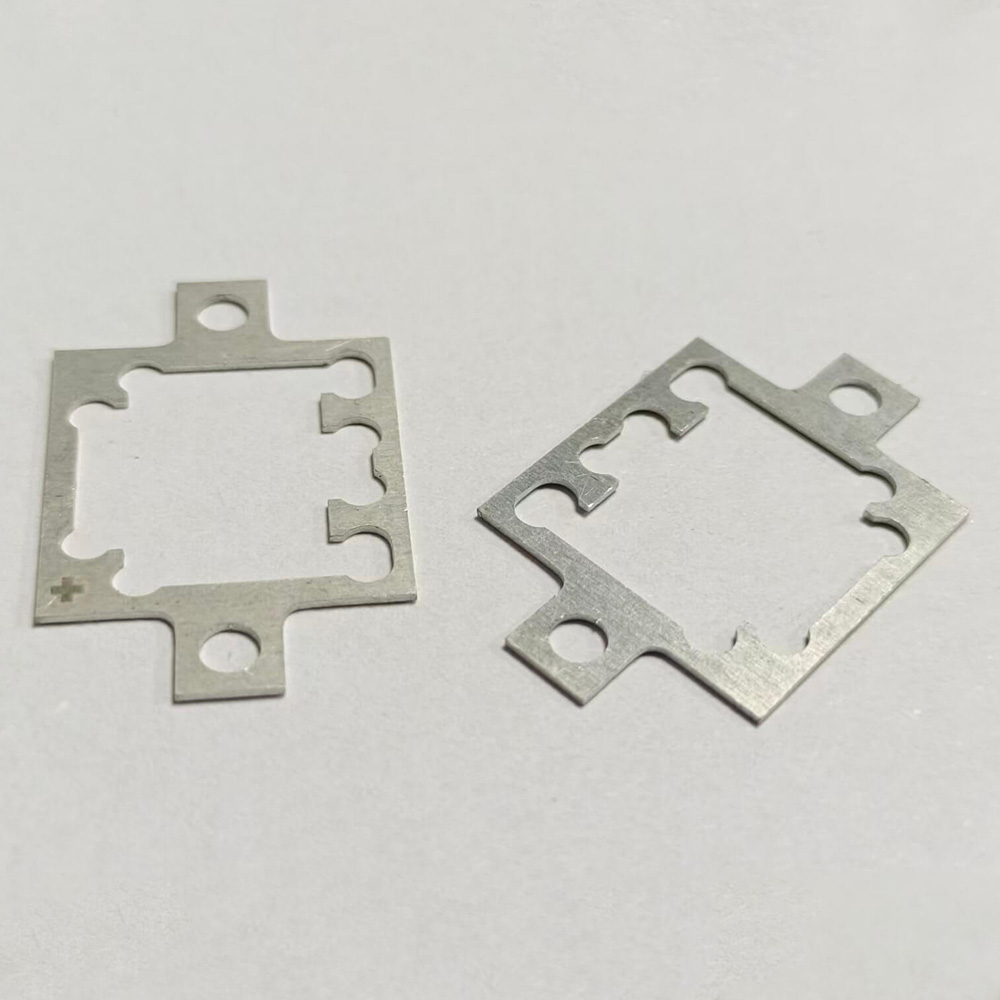

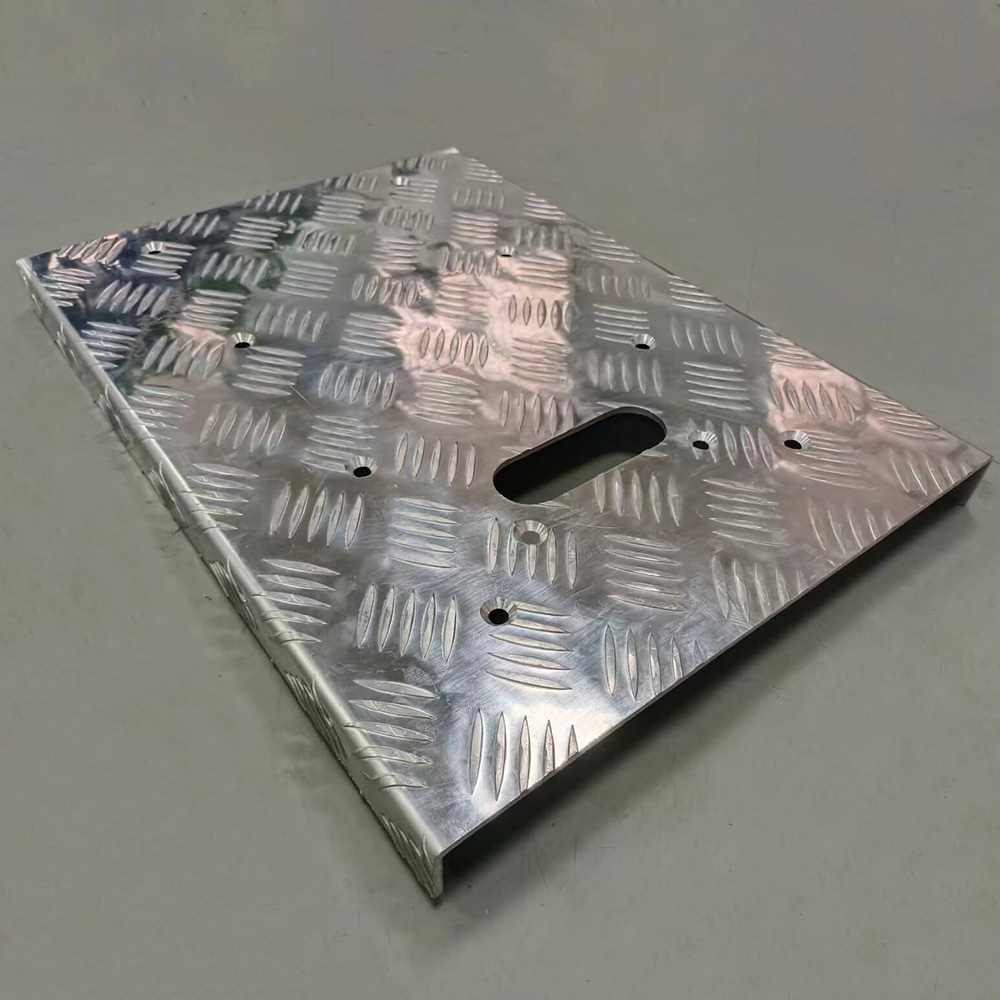

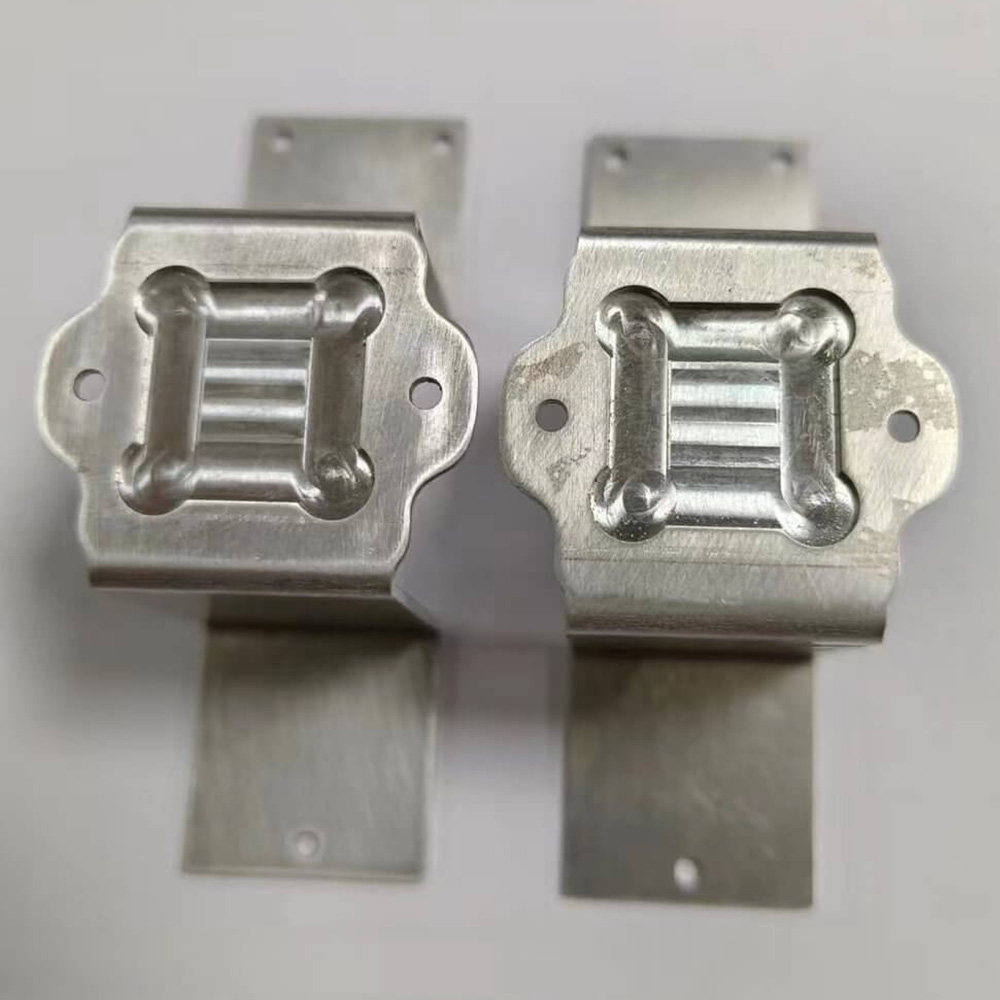

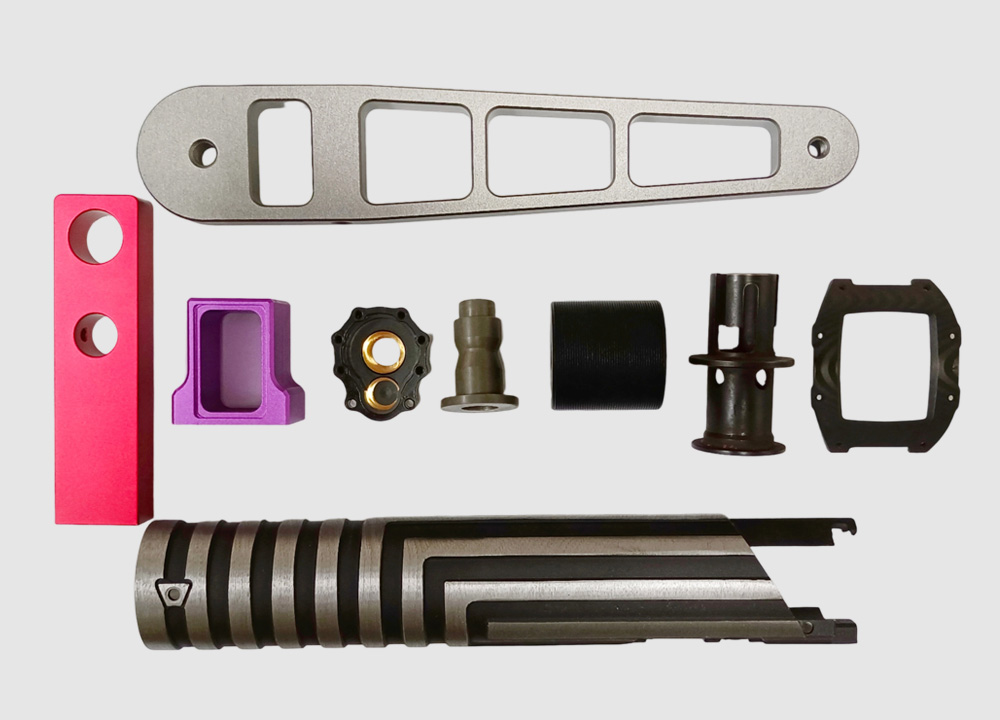

Using state-of-the-art laser cutting, plasma cutting and waterjet cutting systems, we ensure exceptional edge quality, tight dimensional control and minimal material waste.

High-precision cutting for complex geometries and tight tolerances

High-precision cutting for complex geometries and tight tolerances

Material flexibility, ferrous and non-ferrous metals, including reflective materials

Material flexibility, ferrous and non-ferrous metals, including reflective materials

Fast lead times with automated nesting and CNC control

Fast lead times with automated nesting and CNC control

Clean finishes that reduce or eliminate secondary processing

Clean finishes that reduce or eliminate secondary processing

Support for custom and high-volume orders

Support for custom and high-volume orders

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

All Uploads Are Secure and Confidential

All Uploads Are Secure and Confidential

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.