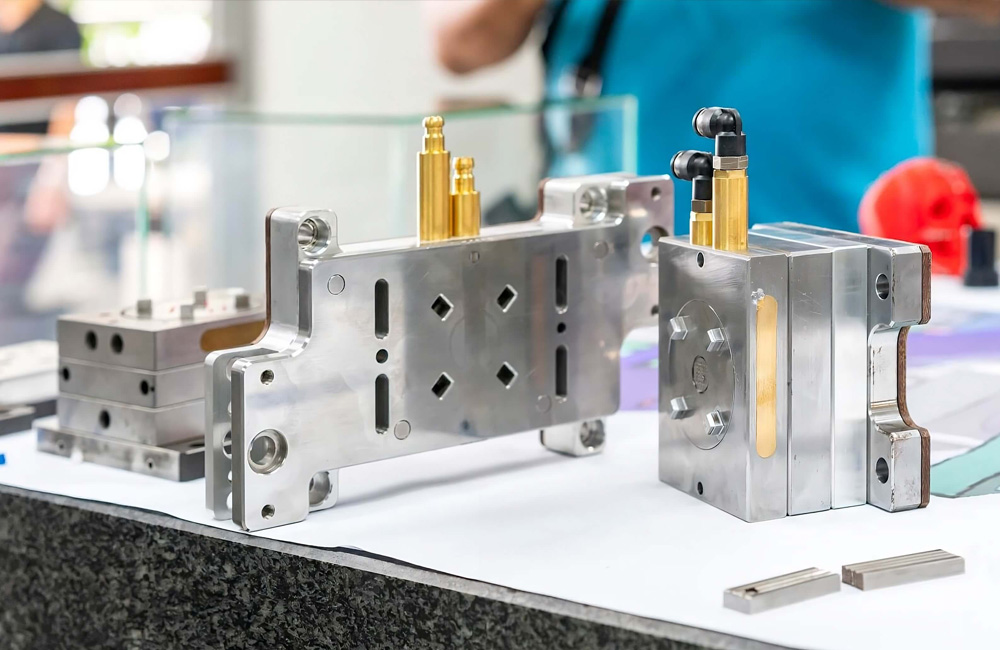

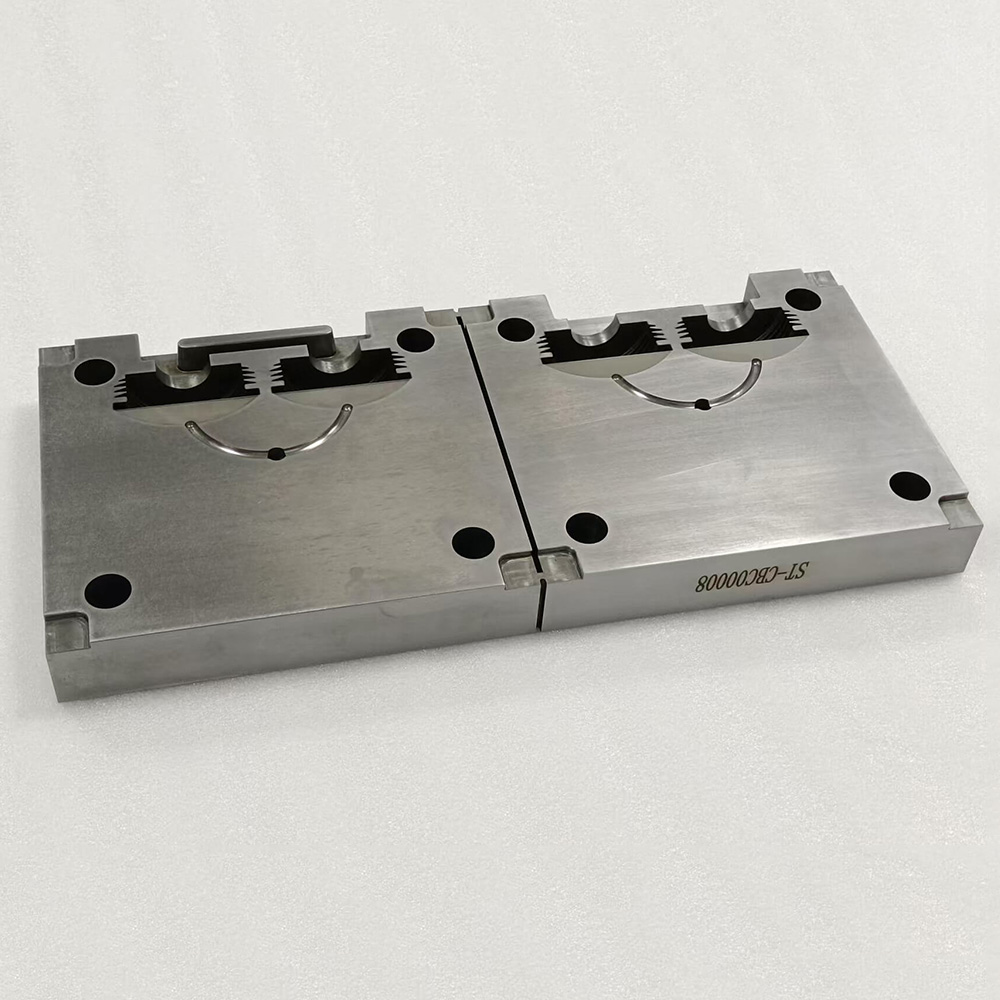

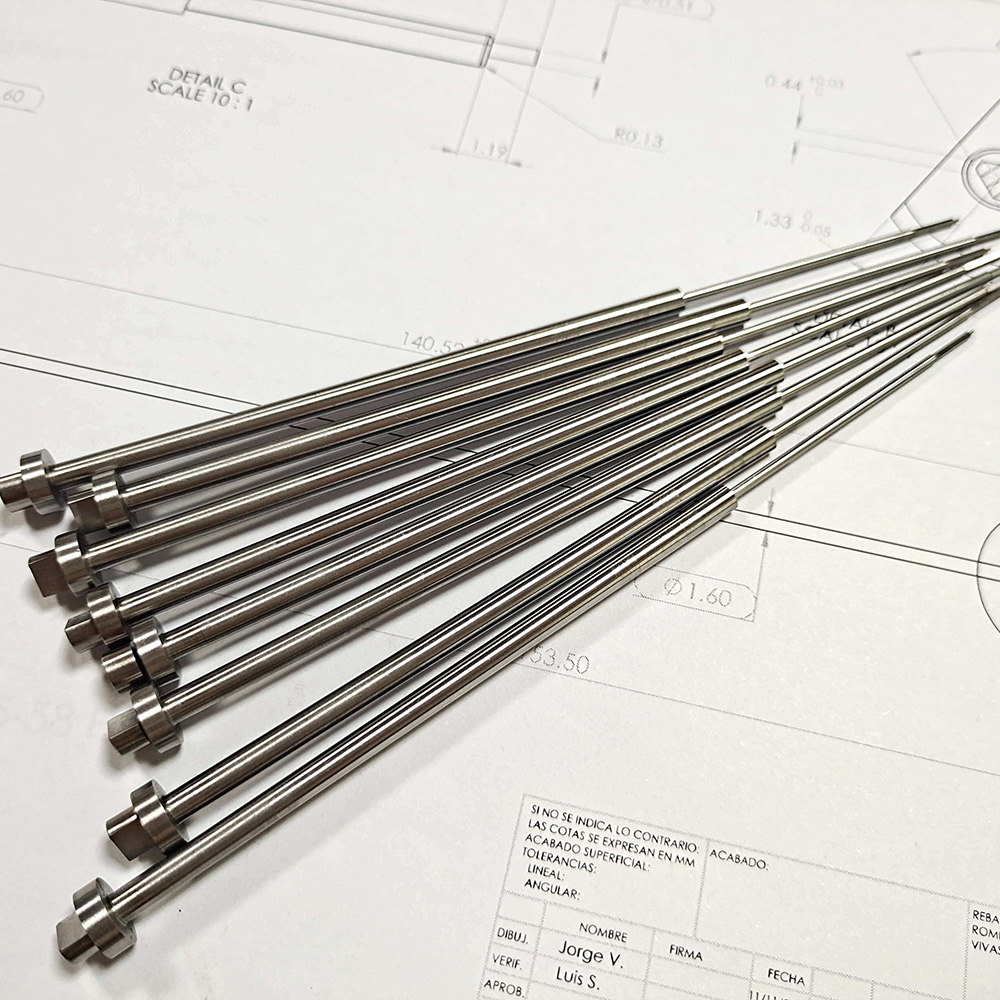

Accelerate development cyclesEnsure tight tolerances and consistent part quality across production runs.

Accelerate development cyclesEnsure tight tolerances and consistent part quality across production runs.

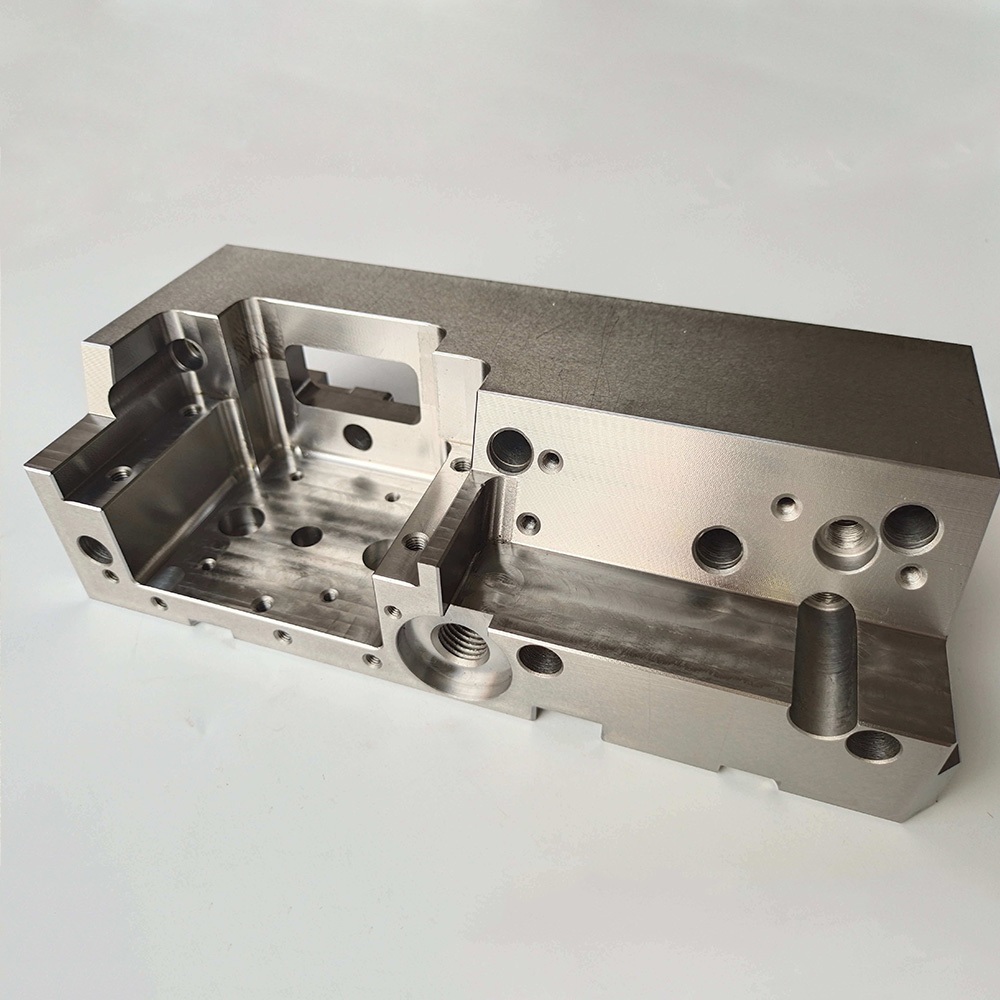

Long Tool LifeBuild with premium materials like hardened steel or aluminum for maximum durability.

Long Tool LifeBuild with premium materials like hardened steel or aluminum for maximum durability.

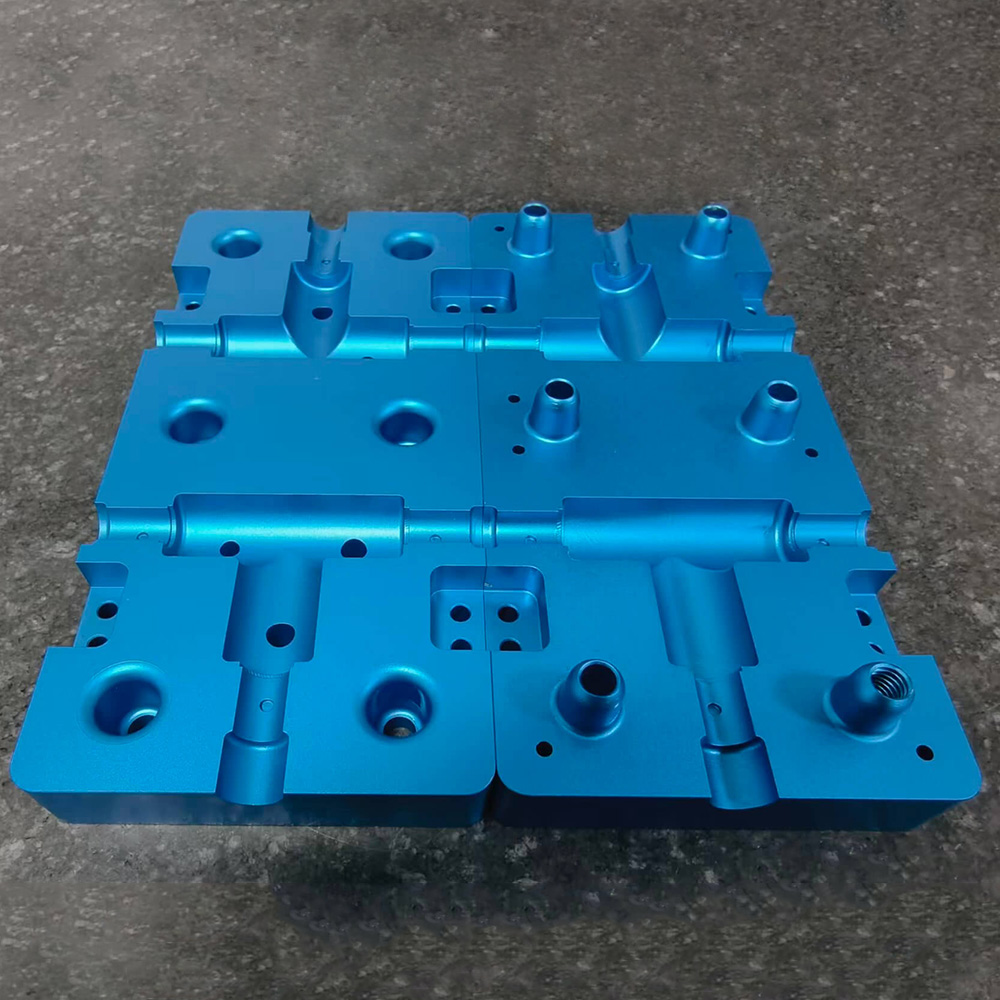

Faster Time-to-MarketEfficient tooling design and fabrication speeds up your product development cycle.

Faster Time-to-MarketEfficient tooling design and fabrication speeds up your product development cycle.

Cost EfficiencyReduce waste, errors and costly rework over the product lifecycle.

Cost EfficiencyReduce waste, errors and costly rework over the product lifecycle.

CustomizableTailored for part complexity, volume requirements, material selection and manufacturing method.

CustomizableTailored for part complexity, volume requirements, material selection and manufacturing method.

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

All Uploads Are Secure and Confidential

All Uploads Are Secure and Confidential

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.