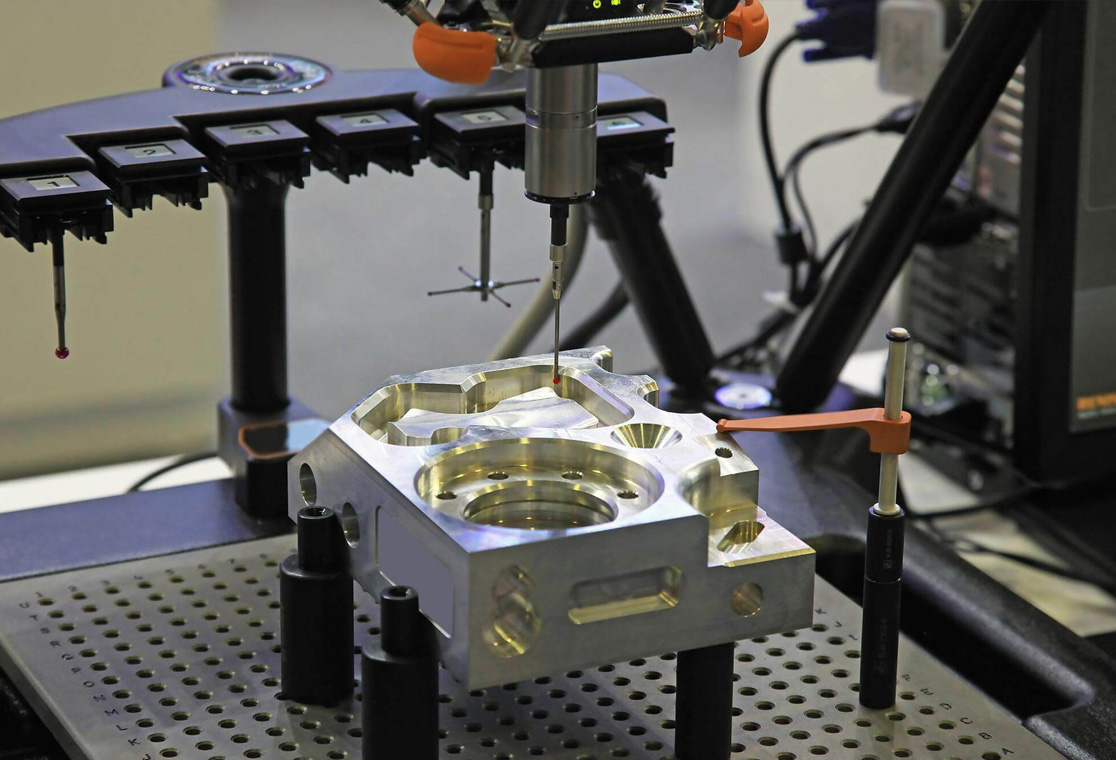

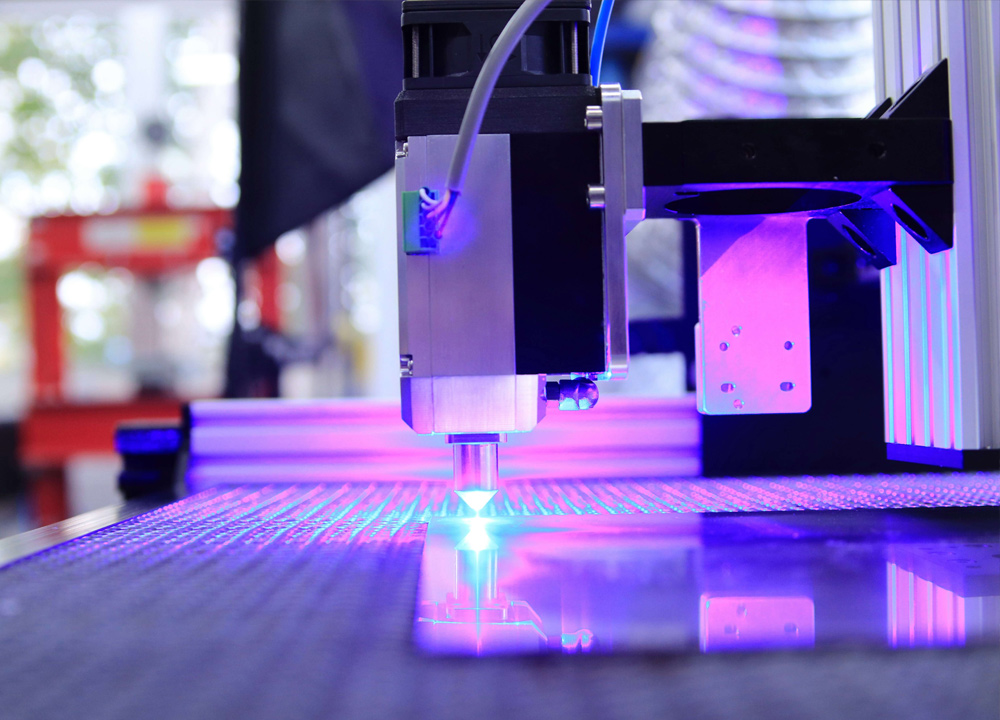

Our approach to quality management goes beyond compliance. Certified by ISO 9001, we have further optimized our customer service processes and enhanced our customer service experience to meet the most demanding project requirements.

Validate part design against applicable standards

Validate part design against applicable standards

Confirm tolerance ranges per engineering drawings

Confirm tolerance ranges per engineering drawings

Verify material certifications and traceability

Verify material certifications and traceability

Follow surface finishing and coating standards

Follow surface finishing and coating standards

Conduct quality checks per professional QA/QC protocols

Conduct quality checks per professional QA/QC protocols

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

Incoming material inspection

Incoming material inspection First article inspection (FAI)

First article inspection (FAI) Dimensional inspection

Dimensional inspection Surface finishing and visual inspection

Surface finishing and visual inspection Final inspection and approval

Final inspection and approval Documentation and traceability

Documentation and traceability Customer-specific quality requirements

Customer-specific quality requirements Packaging checks

Packaging checks

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.