-

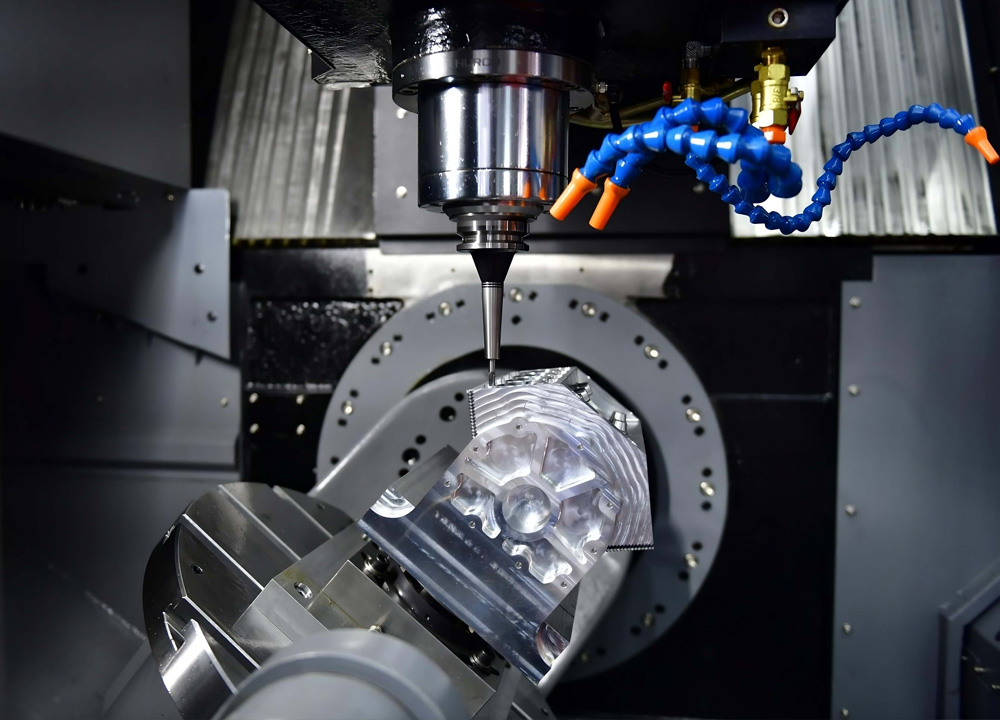

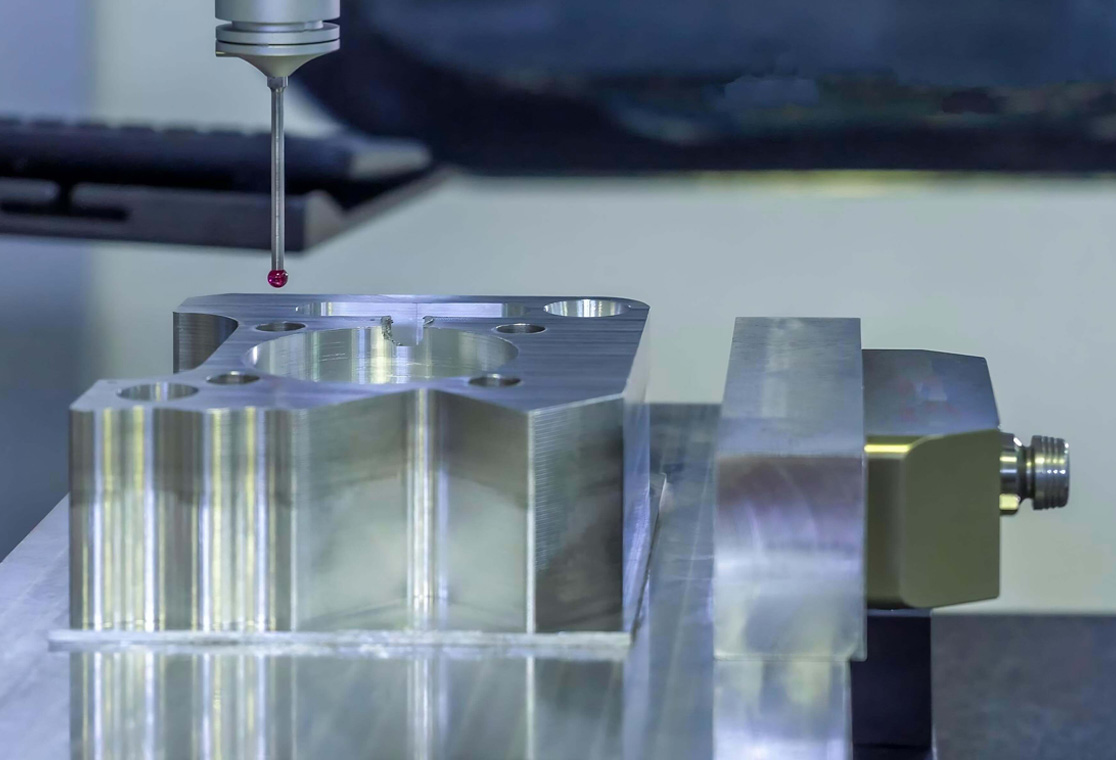

High Precision Guaranteed

We operate advanced CNC milling machines, capable of achieving tight tolerances (as close as ±0.01 mm) for both simple and highly complex components. Whether you're building functional prototypes or end-use parts, precision is our promise. -

Fast Turnaround

Time is critical. Our streamlined production workflow and skilled team ensure your parts are delivered on time—often in as little as 3-7 business days—without compromising quality. -

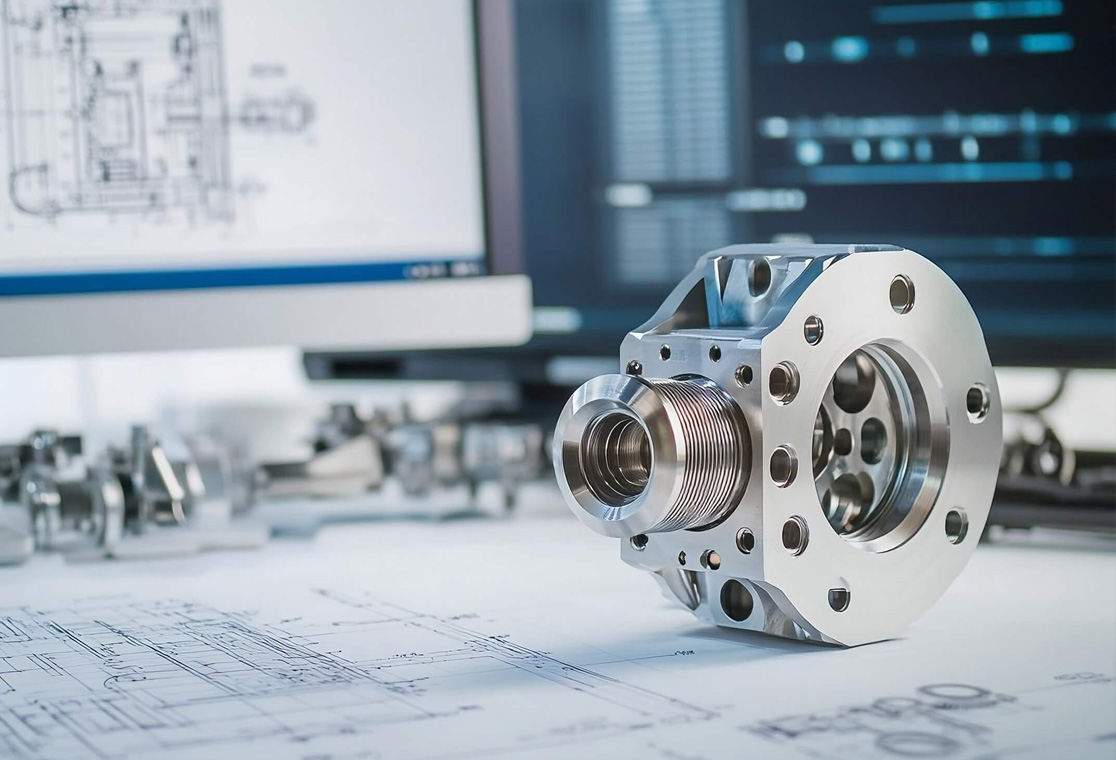

Full Material Versatility

From aluminum, stainless steel and titanium to plastics like ABS, PEEK and Delrin, we support a wide range of materials. This flexibility allows us to meet diverse mechanical, thermal and aesthetic requirements.

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

All Uploads Are Secure and Confidential

All Uploads Are Secure and Confidential

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.