La fabrication sur mesure était autrefois un luxe, un processus réservé aux plus grandes industries et aux produits les plus complexes. Mais aujourd'hui ? C'est un jeu de ball tout différent. Les innovations technologiques ont ouvert les portes à une fabrication plus rapide, plus abordable et hautement personnalisable. Dans cet article, nous allons plonger dans la raison pour laquelle la fabrication sur mesure est devenue plus accessible que jamais, la technologie derrière elle et comment elle transforme les industries dans le monde entier.

La montée de la fabrication sur mesure

La fabrication sur mesure se réfère à la création de produits sur mesure conçus pour répondre à des spécifications uniques plutôt que de produire en masse des articles identiques. Cela pourrait aller d'un seul prototype à un lot limité de pièces. Contrairement à la fabrication traditionnelle, qui est optimisée pour l’efficacité à grande échelle, la fabrication sur mesure s’adapte aux besoins individuels, permettant souvent des variations de conception infinies et une adaptabilité rapide.

La demande de produits personnalisés a explosé au fur et à mesure que les attentes des consommateurs évoluent et que les industries concourent pour offrir des solutions hautement personnalisées. La fabrication sur mesure a gagné en popularité, grâce aux progrès technologiques qui permettent aux entreprises de répondre à ces attentes en évolution sans les longs délais de livraison et les coûts élevés associés à la fabrication traditionnelle.

Des innovations comme l'impression 3D,usinage CNCet l’IA est au cœur de cette transformation. Avec ces outils, les entreprises peuvent rapidement concevoir, prototyper et produire des produits adaptés aux exigences exactes. L’émergence d’outils numériques a également facilité la visualisation, le test et le ajustement des conceptions avant la fabrication, ce qui contribue à réduire les erreurs et le gaspillage de matériaux.

Répondre aux besoins uniques de la fabrication sur mesure

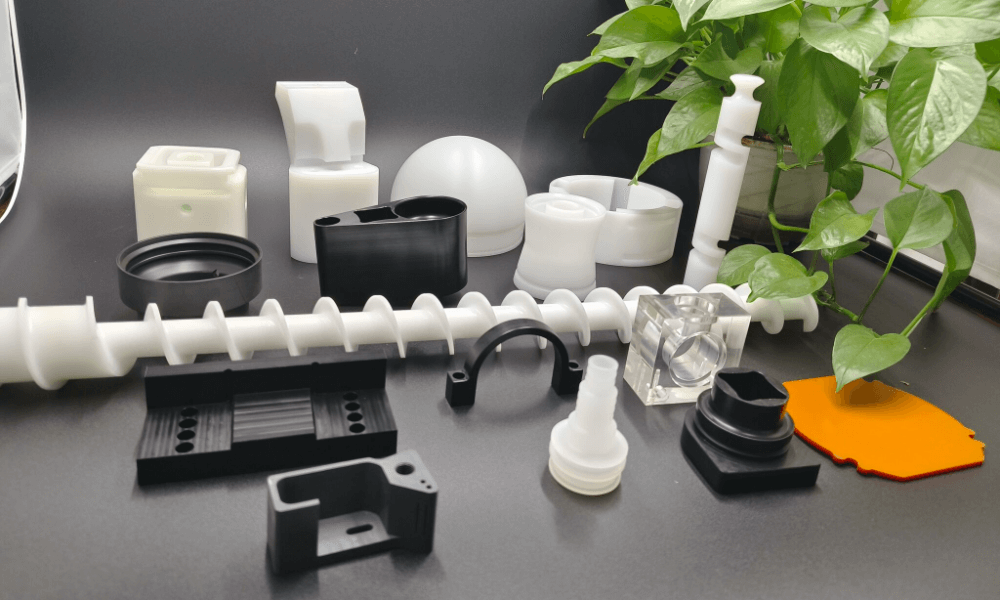

Que ce soit un produit de niche ou une exigence de conception spécifique, la fabrication sur mesure peut répondre à des exigences uniques. Il est idéal pour les industries ayant des besoins spécialisés - pensez aux dispositifs médicaux adaptés à des patients spécifiques, aux pièces automobiles pour les courses haute performance ou à l'électronique grand public personnalisée. La flexibilité de la fabrication sur mesure garantit que les besoins uniques ne signifient pas nécessairement une production complexe ou lente.

La fabrication sur mesure a évolué pour intégrer des méthodes de production plus intelligentes qui aident à minimiser les déchets. En créant des produits basés sur des commandes spécifiques ou des tirages limités, les entreprises évitent l'excès d'inventaire et réduisent les matériaux inutilisés. Cette efficacité n'est pas seulement meilleure pour les entreprises, mais elle est également plus respectueuse de l'environnement, contribuant à la durabilité en réduisant l'utilisation des ressources et le gaspillage.

Un facteur majeur dans la montée de la fabrication sur mesure est l'avancée de la technologie. Sans les outils dont nous disposons aujourd’hui, la personnalisation serait toujours un processus coûteux et chronologique. Regardons quelques technologies clés qui conduisent ce changement.

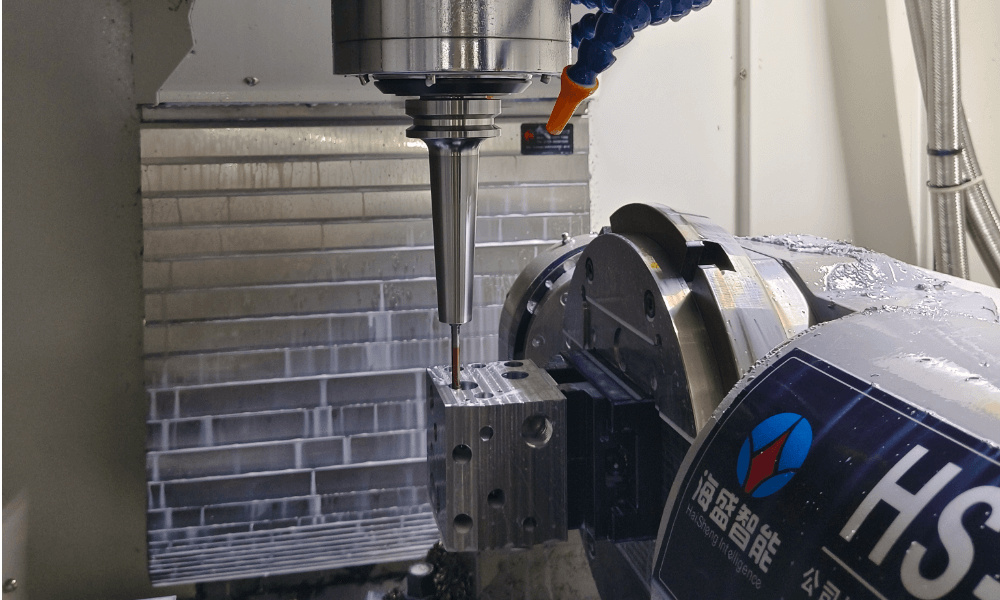

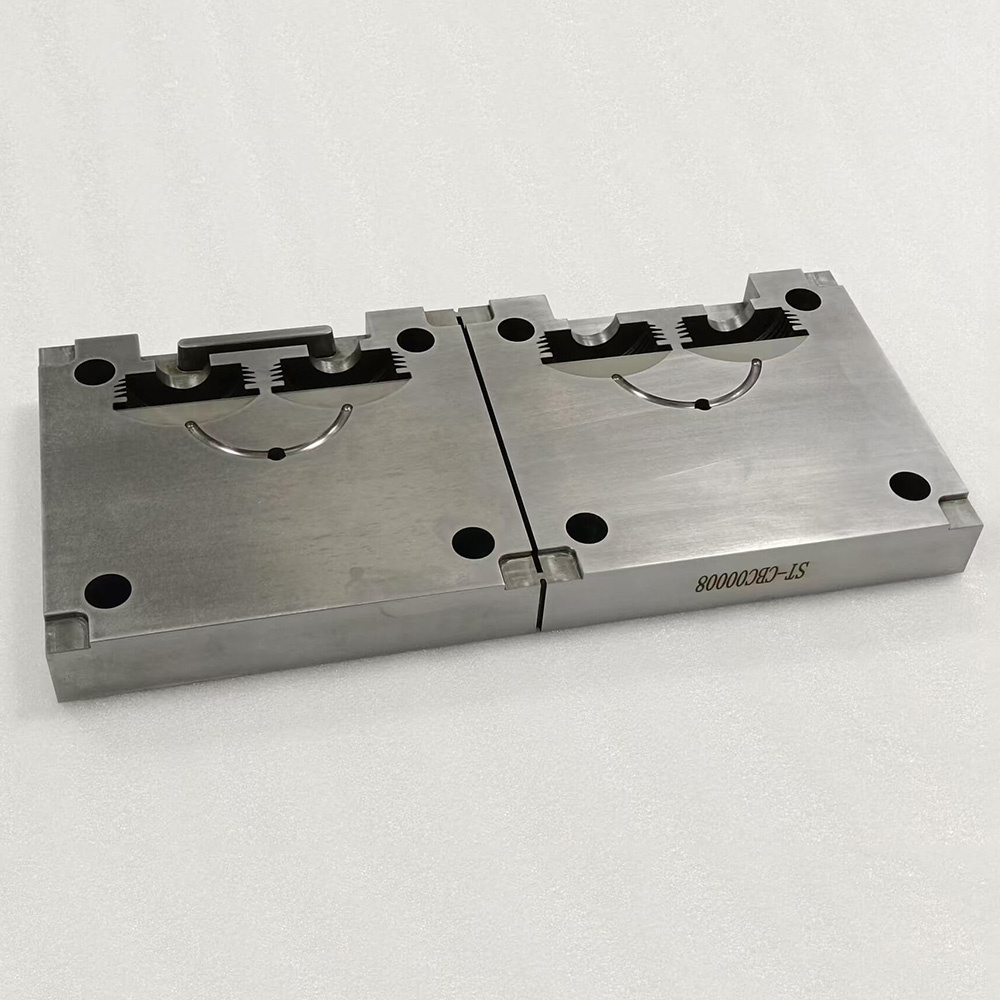

L'usinage CNC est au cœur de la fabrication moderne. La précision et la rapidité sont essentielles pour maintenir la compétitivité dans les environnements de production rapides d'aujourd'hui. L'usinage CNC a révolutionné la précision. Avec des machines contrôlées par ordinateur, les fabricants peuvent produire des pièces très détaillées, atteignant des tolérances allant jusqu'aux millièmes de pouce. L'usinage CNC est idéal pour les matériaux qui nécessitent une coupe précise, comme le métal ou le plastique, ce qui en fait une valeur inestimable pour les industries telles que l'automobile, l'aérospatial et les dispositifs médicaux.

L’impression 3D, ou fabrication additive, a amené le concept de « construire sur commande » à la réalité. Avec l’impression 3D, les fabricants peuvent produire des formes et des géométries complexes que les méthodes traditionnelles ne peuvent pas réaliser. C'est un changement de jeu pour le prototypage et la production de petits lots, permettant des itérations rapides et un gaspillage minimum.

L’IA et l’apprentissage automatique ont amélioré les processus de fabrication personnalisés en permettant la maintenance prédictive, l’optimisation des conceptions et l’automatisation du contrôle de qualité. Ces technologies aident à identifier les défauts tôt et à suggérer des optimisations, rendant la fabrication plus efficace et réduisant les temps d’arrêt.

Grâce à la technologie avancée, la fabrication sur mesure a beaucoup à offrir au-delà de simples designs sur mesure. Des délais de livraison rapides à une qualité supérieure, les avantages sont tangibles et de grande portée.

Dans des industries concurrentielles, la vitesse est essentielle. La fabrication sur mesure raccourcit le temps entre le concept et la disponibilité du produit. Au lieu d’attendre de longues séries de production, les entreprises peuvent mettre leurs produits sur le marché plus rapidement, ce qui est crucial pour rester en avance dans des secteurs en évolution rapide.

Avec des outils tels que l'usinage CNC et la coupe laser, la fabrication sur mesure atteint des niveaux de précision qui n'étaient pas possibles auparavant. Cette haute précision assure une qualité constante, ce qui est particulièrement important dans les domaines où un seul défaut pourrait conduire à une défaillance, comme dans l'aérospatial ou les soins de santé.

Plus important encore, de plus en plus d’entreprises utilisent la fabrication sur mesure pour le prototypage, leur donnant la flexibilité d’itérer et d’améliorer rapidement leurs conceptions. Une fois perfectionnés, ces prototypes peuvent rapidement évoluer en produits finaux, permettant une progression fluide de la conception à la production.

Industries prospères sur la fabrication sur mesure

Certaines industries bénéficient de la fabrication sur mesure plus que d'autres en raison de leurs exigences uniques et de leurs normes élevées. Voici quelques secteurs qui tirent le meilleur parti de cette technologie.

Les industries aérospatiale et automobile ont adopté la fabrication sur mesure pour créer des composants légers, durables et conçus avec précision. Avec l'usinage CNC, les entreprises aérospatiales peuvent fabriquer des pièces complexes, tandis que l'industrie automobile utilise la fabrication sur mesure pour des composants spécialisés tels que des moteurs sur mesure, des panneaux de carrosserie et des pièces de performance.

La fabrication sur mesure a permis à l’industrie technologique d’innover avec de nouveaux designs pour l’électronique grand public et les appareils portables. Il permet aux fabricants d'expérimenter de nouvelles formes audacieuses, de conceptions ergonomiques et de matériaux pour répondre aux demandes des consommateurs en matière de gadgets personnalisés.

Étapes pour commencer avec la fabrication sur mesure

La fabrication sur mesure transforme un concept en un produit réel et tangible. Contrairement à la production en masse, chaque projet sur mesure nécessite une planification délibérée, une communication précise et des bases d'ingénierie solides.

Que vous fabriquez des pièces de moto de prototype, des supports aérospatiaux, des boîtiers électroniques ou des produits de consommation, ce sont les étapes exactes pour démarrer correctement un projet de fabrication sur mesure.

Commencez par définir clairement les exigences de votre produit. De quoi avez-vous besoin en termes de matériaux, de dimensions, de durabilité et de fonctionnalité ? Être spécifique à ce stade permettra de gagner du temps et des ressources sur la route.

La fabrication sur mesure nécessite un partenariat avec des professionnels qualifiés qui peuvent donner vie à votre vision. Des fabricants expérimentés peuvent vous guider dans les ajustements de conception, recommander des matériaux et optimiser le processus de production.

Résumé

La fabrication sur mesure n’a jamais été aussi accessible, précise ou adaptable. Les technologies à notre disposition ont redéfini ce qui est possible, permettant aux individus et aux entreprises de créer des produits sur mesure qui s’alignent parfaitement sur leurs visions. Que vous réalisiez une pièce unique ou une petite série de production, la flexibilité et l'efficacité de la fabrication sur mesure en font un outil puissant pour n'importe quelle industrie. Alors, pourquoi attendre ? Embrassez le monde de la fabrication sur mesure et faites de vos idées une réalité aujourd'hui.

+86 15338350382

+86 15338350382

Français

Français Anglais

Anglais Espagnol

Espagnol Russe

Russe Italien

Italien Allemand

Allemand Japonais

Japonais

10 Min lecturePublié Dec 15 2025

10 Min lecturePublié Dec 15 2025

sophia@alcrocn.com

sophia@alcrocn.com

86 15338350382

86 15338350382

6ème rue nord, communauté de Xiagang, ville de Chang'an, ville de Dongguan, province du Guangdong, Chine.

6ème rue nord, communauté de Xiagang, ville de Chang'an, ville de Dongguan, province du Guangdong, Chine.