-

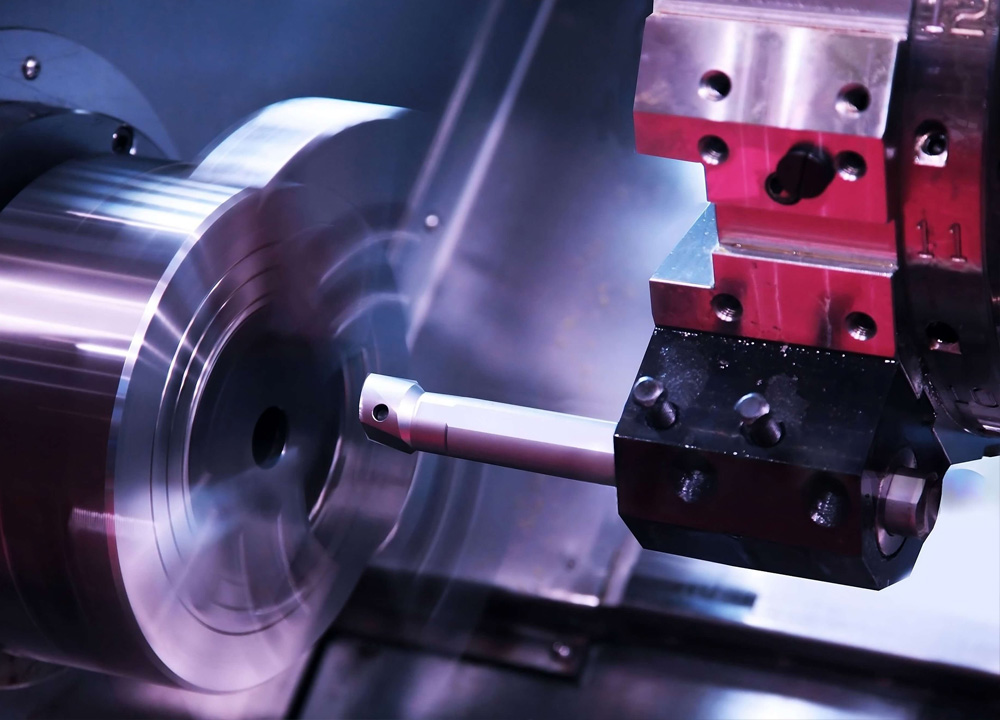

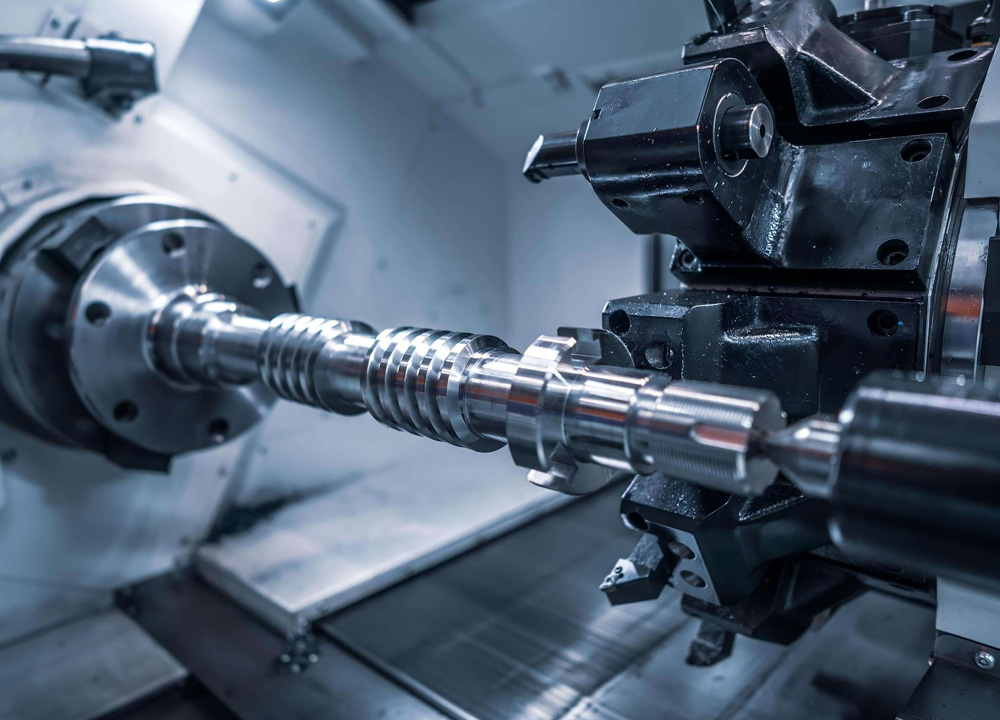

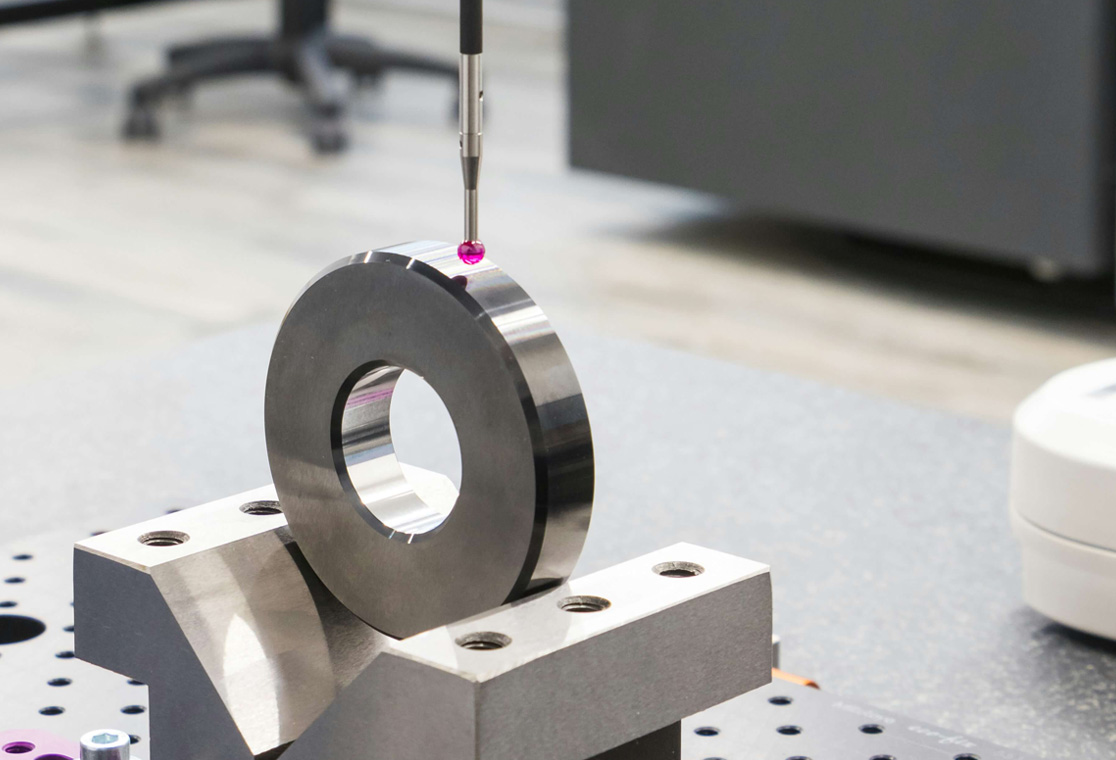

Präzision, auf die Sie sich verlassen können

Unsere CNC-Drehmaschinen – einschließlich 2-Achsmaschinen, Mehrachs-Drehzentren und Drehmaschinen des Schweizer Typs – sind ausgestattet, um komplexe Geometrien und enge Toleranzen bis zu ±0,002 mm zu verarbeiten, so dass jedes Teil Ihren genauen Spezifikationen entspricht. -

Vielseitige Bearbeitungsmöglichkeiten

Von einfachen Wellen bis hin zu vielfältigen Komponenten kombinieren wir Drehen, Bohren, Abtappen und Fräsen in einem Aufbau, um die Produktion zu rationalisieren und Kosten und Lieferzeiten zu reduzieren. -

Schnelle Umsetzung und skalierbare Produktion

Benötigen Sie schnelle Prototypen oder eine großflächige Fertigung? Unser flexibles Produktionssystem ermöglicht eine schnelle Lieferung, ohne die Präzision zu beeinträchtigen – egal ob es sich um ein Teil oder zehntausend handelt.

+86 15338350382

+86 15338350382

German

German English

English Spanish

Spanish French

French Russian

Russian Italian

Italian Japanese

Japanese

Alle Uploads sind sicher und vertraulich

Alle Uploads sind sicher und vertraulich

sophia@alcrocn.com

sophia@alcrocn.com

86 15338350382

86 15338350382

6. Nordstraße, Xiagang-Gemeinschaft, Chang'an-Stadt, Dongguan-Stadt, Guangdong-Provinz, China.

6. Nordstraße, Xiagang-Gemeinschaft, Chang'an-Stadt, Dongguan-Stadt, Guangdong-Provinz, China.