|

Особенность

|

Рекомендация по проектированию

|

Примечания / Лучшие практики

|

|

Толерантности

|

Применять жесткие допуски только там, где это функционально необходимо

|

Более свободные допуски уменьшают затраты и время поставки без жертвы функцией.

|

|

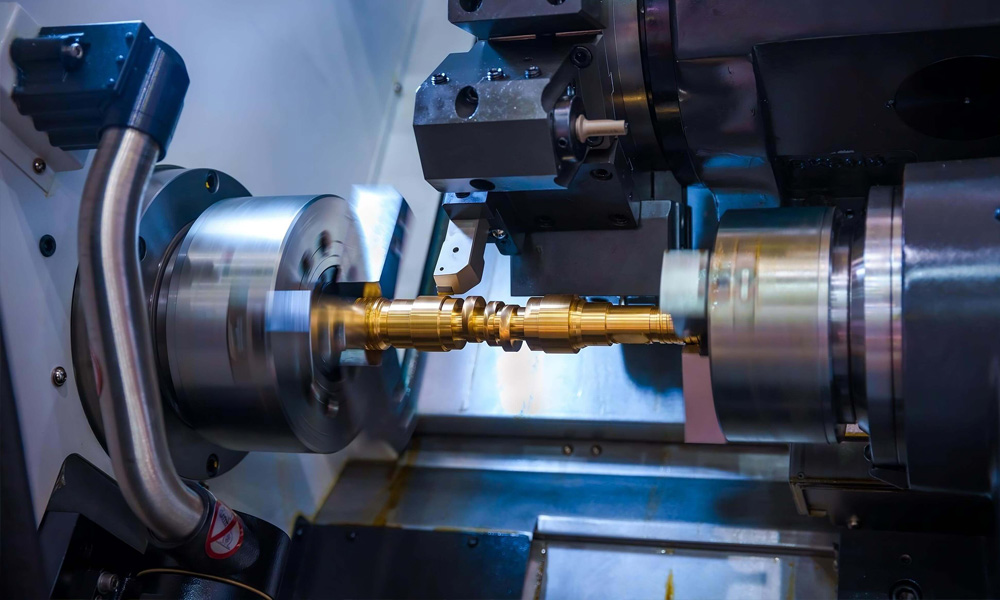

Толщина стены

|

Поддерживать минимальную толщину стены ≥1 мм для металлов

|

Тонкие стены могут вибрировать или деформироваться во время обработки.

|

|

Размеры отверстий

|

Стандартные размеры отверстий (например, Ø3, Ø6, Ø10 мм)

|

Стандартные размеры сверл более экономичны и быстрее обрабатывать.

|

|

Глубины отверстий

|

Держите глубину ≤3 × диаметр для слепых отверстий

|

Более глубокие отверстия требуют специальных инструментов или сверления.

|

|

Внутренние радиусы

|

Используйте филе радиусом ≥0,5 мм во внутренних углах

|

Острые углы трудно обрабатывать и увеличивают износ инструмента.

|

|

Подрезания

|

Избегайте или четко указывайте подрезы

|

Требуются пользовательские инструменты или вторичные операции.

|

|

-ed Особенности

|

Используйте стандартные размеры нитей (например, M6, ¼-20) и избегайте нитей слишком близко к краям

|

Позвольте достаточное размещение для задействования инструмента.

|

|

Плоскость & Параллелизм

|

Указать только когда критическое значение для функции

|

Может увеличить время обработки; использовать GD&Т, где это уместно.

|

|

Окончательная поверхность

|

Соответствует функции (например, Ra 1,6-3,2 мкм для большинства металлических частей)

|

Более тонкие отделки часто требуют шлифовки, полировки или медленной обработки.

|

|

Симметрия части

|

Используйте симметричные конструкции, когда это возможно

|

Помогает в фиксации и уменьшает сложность установки.

|

|

Текст/логотипы

|

Используйте гравированный текст глубиной ≥0,5 мм, с простыми шрифтами

|

Небольшие или декоративные шрифты могут не обрабатываться чисто.

|

|

Выбор материала

|

Выбор материалов на основе прочности и Обрабатываемость

|

Примеры: алюминий 6061-T6 (легкий), нержавеющая сталь (сложный).

|

+86 15338350382

+86 15338350382

Русский

Русский Английский

Английский Испанский

Испанский Французский

Французский Итальянский

Итальянский Немецкий

Немецкий JАпанез

JАпанез

Все загрузки безопасны и конфиденциальны

Все загрузки безопасны и конфиденциальны

sophia@alcrocn.com

sophia@alcrocn.com

86 15338350382

86 15338350382

6-я северная улица, сообщество Сяганг, город Чанань, город Донггуан, провинция Гуандун, Китай.

6-я северная улица, сообщество Сяганг, город Чанань, город Донггуан, провинция Гуандун, Китай.