|

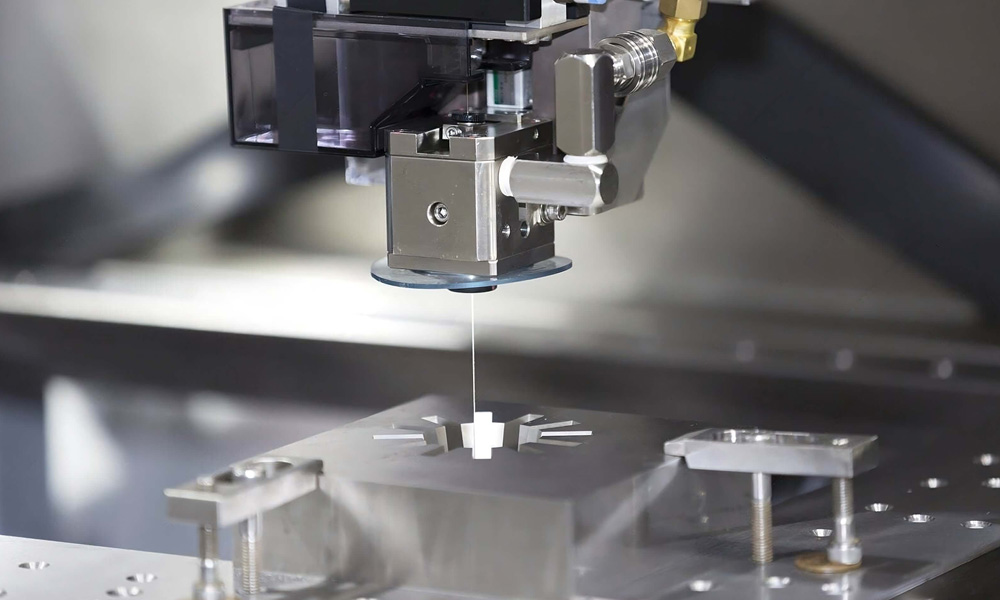

特性

|

設計上の推奨事項

|

注意事項/ベストプラクティス

|

|

公差公差

|

機能が必要な場合にのみ厳しい許容差を適用

|

よりゆとりのある許容差により、機能を犠牲にすることなくコストと納期を削減できます。

|

|

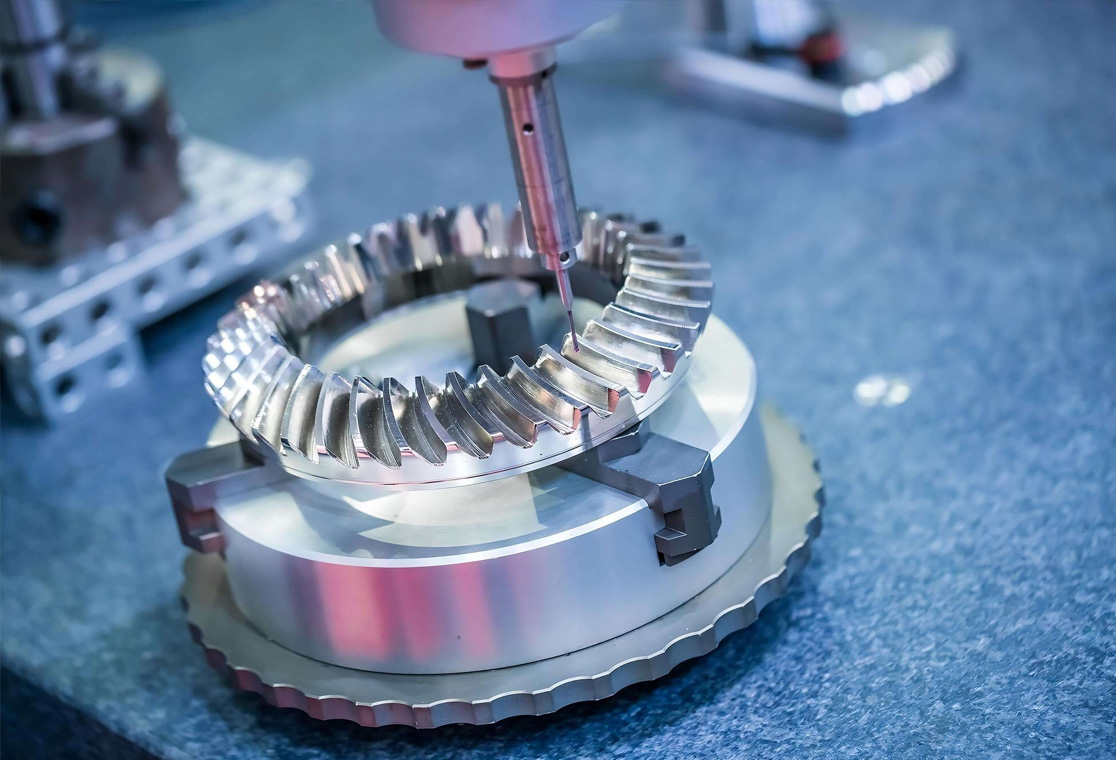

壁厚

|

金属材料については、最小壁厚が1ミリメートル以上である必要があります。

|

薄肉部は加工中に振動や変形が生じる可能性があります。

|

|

穴の寸法

|

設計標準穴寸法(例:Ø3、Ø、6、呲10 mm)

|

標準ドリルのサイズはより経済的で、加工速度はより速い。

|

|

ドリル深さ

|

ブラインド穴深さ≦3×直径

|

深い穴には特殊なツールや穴が必要です。

|

|

ないぶはんけい

|

内角は半径≧0.5 mmのフィレットを使用する

|

尖った角は加工が難しく、工具の摩耗が増加します。

|

|

アンダーカット

|

アンダーカットを回避または明確に規定する

|

カスタムツールまたは補助操作が必要です。

|

|

-ed機能

|

標準ねじ寸法(M 6、188-20など)を使用して、ねじがエッジに近づきすぎないようにします

|

工具の接合に十分な隙間を空ける。

|

|

平坦度 & へいこうせい

|

機能キー時にのみ指定

|

加工時間を増やすことができます。GDを使用&Tは適当な時に。

|

|

表面処理

|

機能整合(例えば、ほとんどの金属部品のRaは1.6〜3.2µm)

|

より微細な表面処理には、通常、研磨、研磨、または緩慢な加工プロセスが必要である。

|

|

部品の対称性

|

できるだけ対称設計を使用する

|

設定の複雑さを固定して軽減するのに役立ちます。

|

|

テキスト/ロゴ

|

深さ≧0.5 mmの彫刻文字を使用し、フォントが簡単

|

小さなフォントや装飾フォントは不潔かもしれません。

|

|

材料選択

|

強度と 機械加工性

|

例:6061-T 6アルミニウム(易)、ステンレス(難)。

|

+86 15338350382

+86 15338350382

日本語

日本語 英語

英語 スペイン語

スペイン語 フランス語

フランス語 ロシア

ロシア イタリア語

イタリア語 ドイツ語

ドイツ語

すべてのアップロードは安全で機密です

すべてのアップロードは安全で機密です

sophia@alcrocn.com

sophia@alcrocn.com

86 15338350382

86 15338350382

中国広東省東莞市長安鎮の一時帰休コミュニティ北六街。

中国広東省東莞市長安鎮の一時帰休コミュニティ北六街。