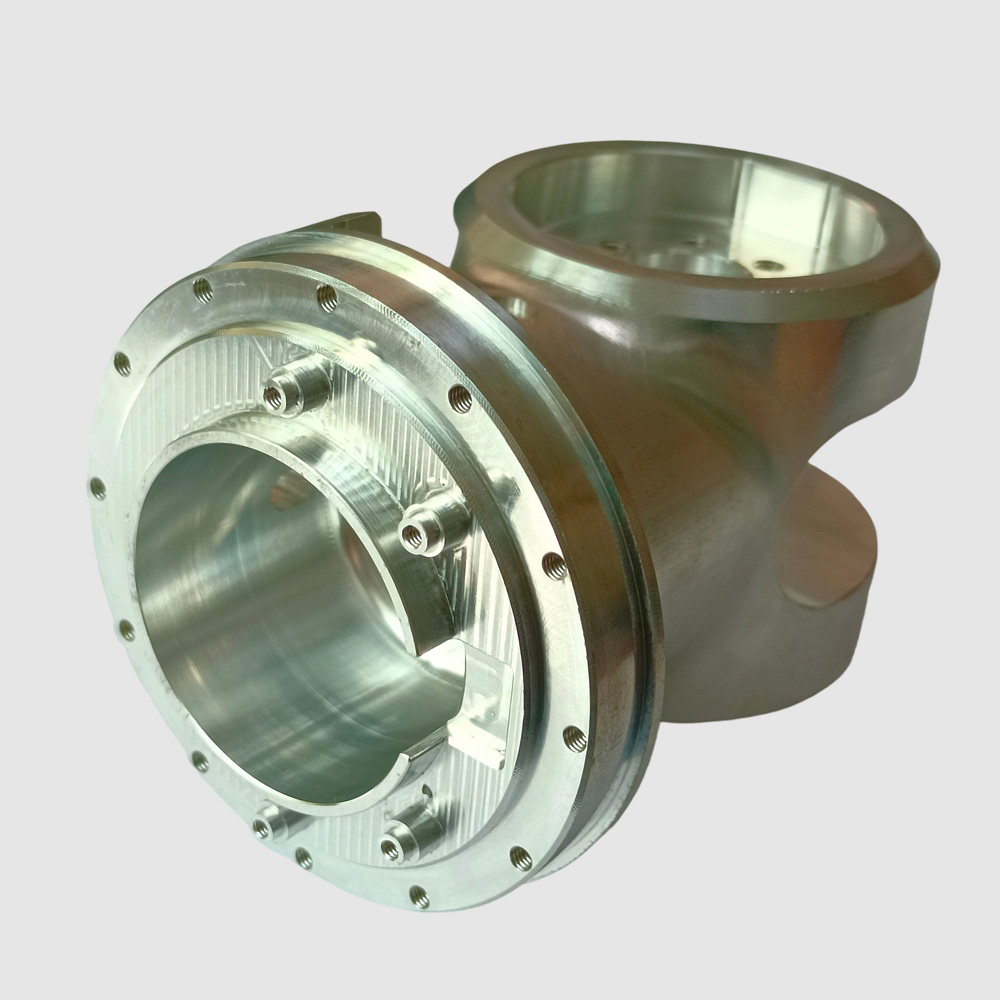

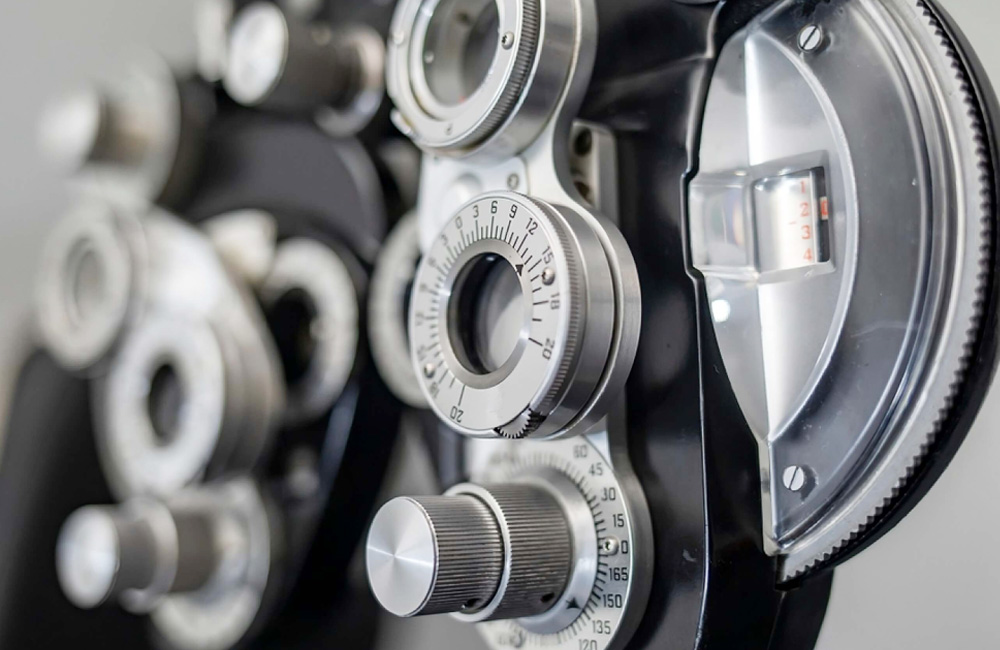

In the medical device industry, precision, safety and performance are non-negotiable. Every device must function flawlessly in life-critical environments—and that’s where custom manufacturing becomes essential. Unlike off-the-shelf components, custom-manufactured parts are designed and built to meet the unique clinical, mechanical and regulatory requirements of each product.

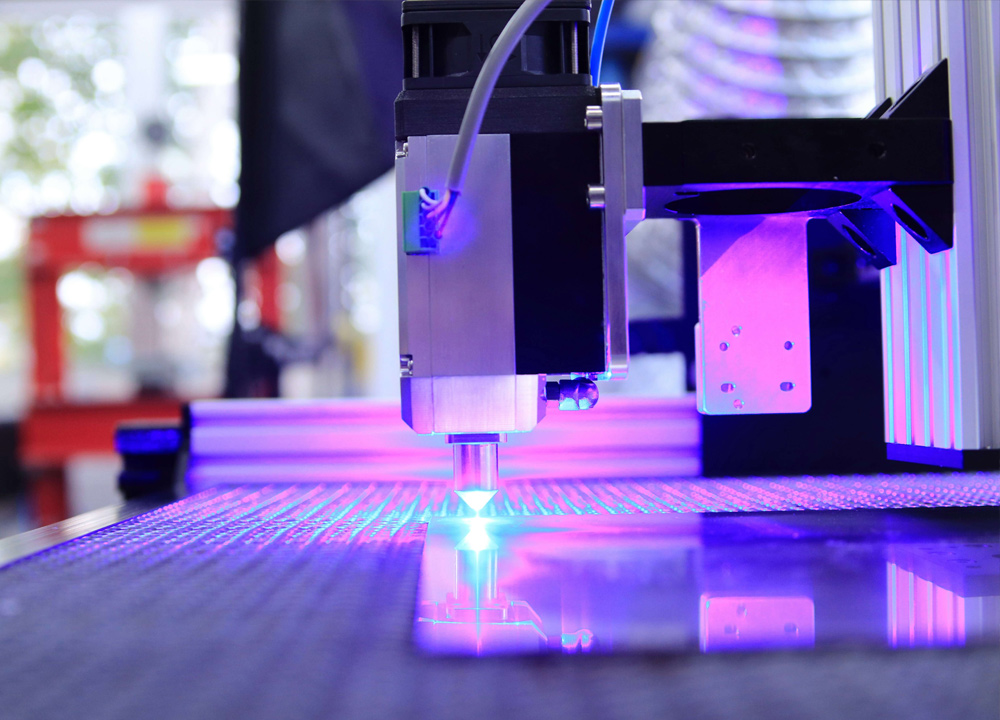

With advanced CNC machining and deep expertise in medical-grade materials, we combine cutting-edge manufacturing technologies, stringent quality controls and deep industry expertise to deliver components that meet the strictest performance and regulatory requirements.

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

All Uploads Are Secure and Confidential

All Uploads Are Secure and Confidential

Patient-specific and product-specific solutions

Patient-specific and product-specific solutions

Milling, Turning, EDM and Grinding processes available

Milling, Turning, EDM and Grinding processes available

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.