What Is First Article Inspection?

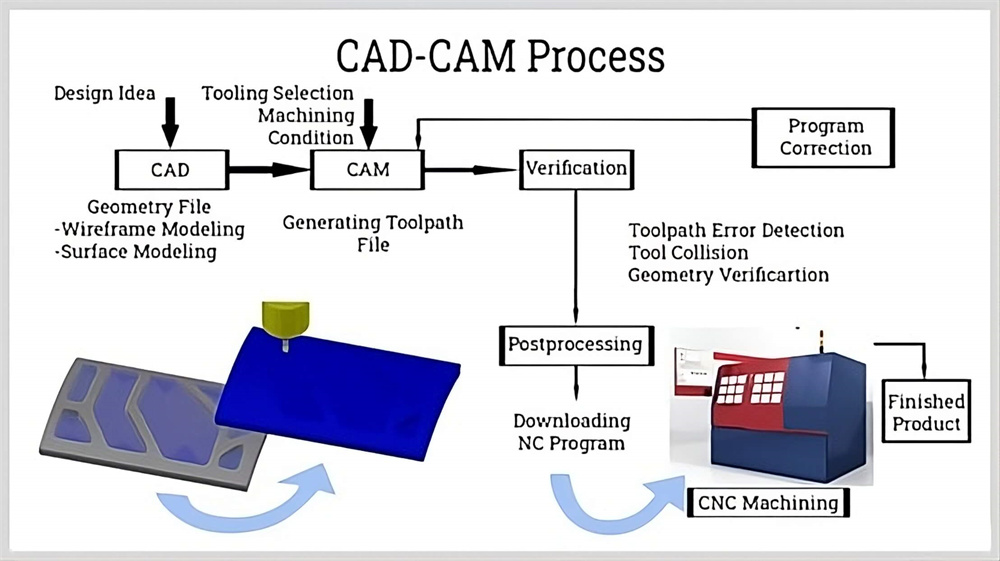

First Article Inspection (FAI) is a critical quality assurance process in CNC machining. Its purpose is to verify that the first part produced from a new CNC program, fixture setup, or design revision meets all specifications, ensuring production readiness before full-scale manufacturing.

For manufacturers and customers alike, FAI provides:

· Verification of dimensional accuracy

· Confirmation of material and process compliance

· Assurance of repeatable, stable production

· Early identification of potential issues

Callout: FAI is not just a“measurement check”—it is a process validation tool that protects your investment, prevents scrap, and ensures quality from day one.

Why FAI Matters for Your Project

CNC machining tolerances are extremely tight—often ±0.01mm—making FAI indispensable.

Key Benefits

|

Benefit |

Description |

| Dimensional Accuracy |

Confirms all features match drawings and GD&T requirements |

| Process Validation |

Verifies CNC program, tooling, and fixturing setup |

| Material Compliance |

Checks material grade, heat treatment, and surface finishes |

| Risk Mitigation |

Identifies issues before mass productio |

|

Traceability |

Provides documented evidence for audits or regulatory compliance |

Callout: In aerospace, medical, and high-precision industrial sectors, FAI is often mandatory for new parts or suppliers.

When Do CNC Machined Parts Require FAI?

CNC machined parts require FAI under the following conditions:

· The part is new or hasn't been produced before

· The design has revisions or tolerance changes

· There is a change in material, process, or tooling

· Production moves to a new supplier or facility

· The part has tight tolerances, is safety-critical, or has strict cosmetic requirements

Callout: If a part is unchanged and the process is proven, FAI may be waived, but customer approval is always recommended. If you’re unsure, our team will advise you.

What We Check During FAI

1. Dimensional Accuracy

· CMM measurement of all critical features

· Holes, threads, pockets, profiles, flatness, position

· Comparison against tolerances and GD&T requirements

2. Material & Certification Verification

· Material grade confirmation

· Heat treatment or hardness reports

· Surface finish and coating checks

3. Visual & Functional Checks

· Deburring, edges, and surface quality

· Cosmetic finish review

· Basic assembly fit if applicable

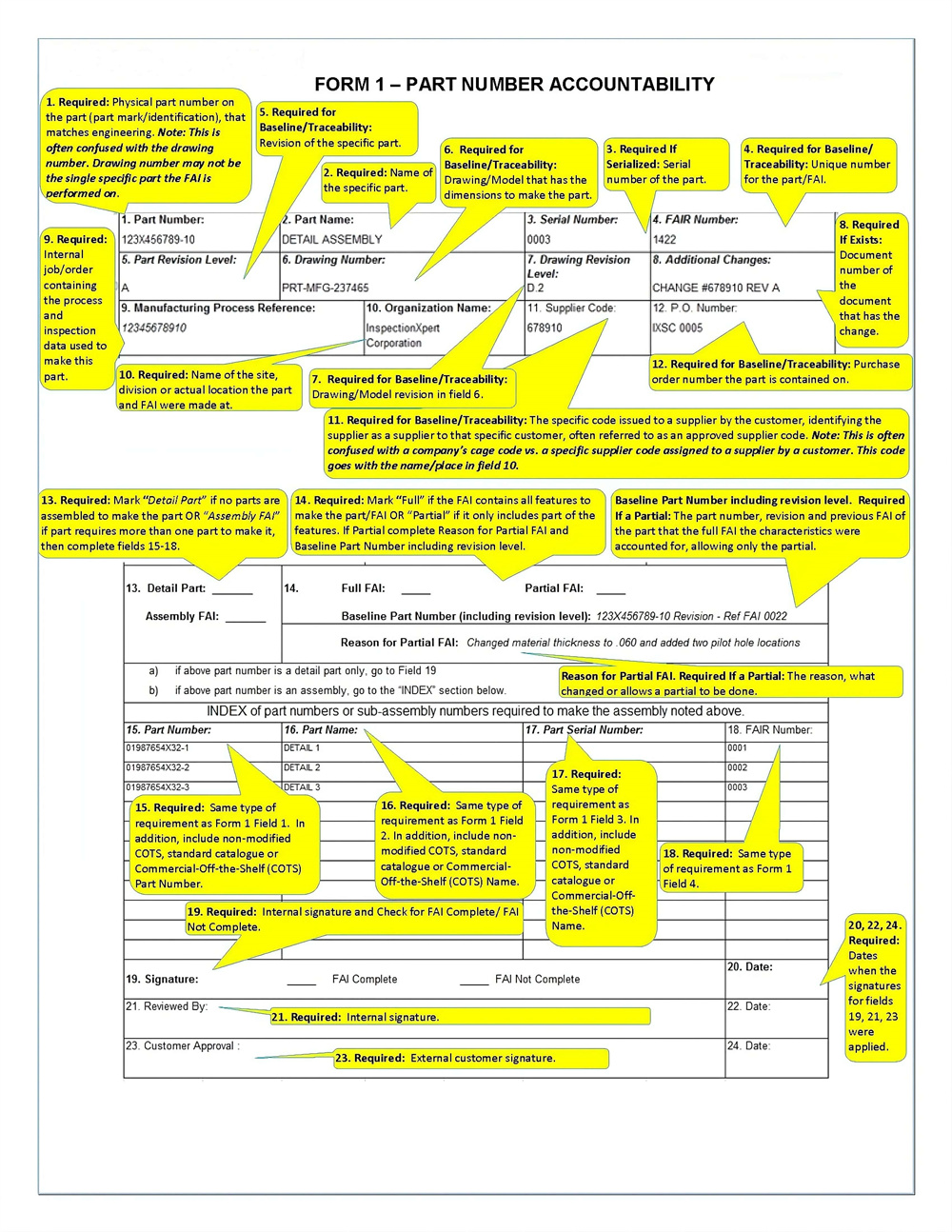

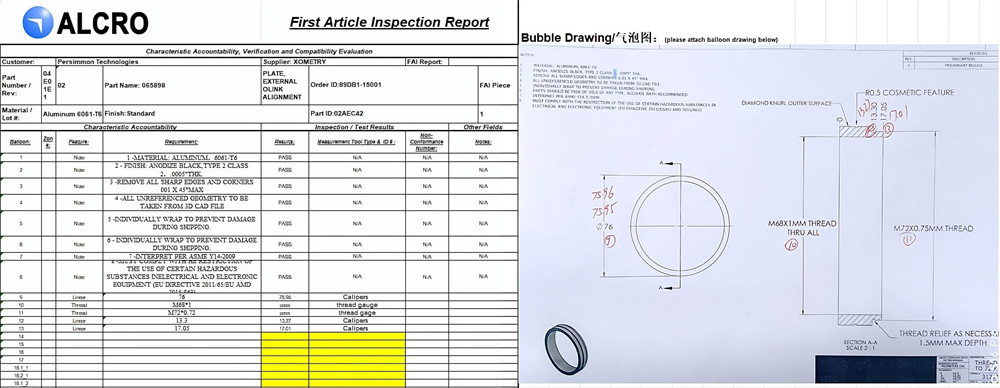

What You Receive in an FAI Package

Your FAI documentation typically includes:

· FAI inspection report (internal or AS9102 format)

· Full dimensional results with pass/fail

· Ballooned engineering drawing

· Material certificates and process reports

· Photos of the inspected first article

Callout: This documentation can be shared with your quality team or included in your internal audit trail.

Lead Time and Cost Expectations

FAI adds:

· 1–5 business days depending on part complexity

· A small documentation and measurement fee

Callout: This investment prevents batch-level scrap, quality disruptions, and delays—especially on complex CNC components.

How to Ensure a Smooth FAI Process

To help us deliver an accurate first article the first time, please provide:

· Clear 2D engineering drawings with tolerances

· A 3D model (STEP/Parasolid)

· Any Critical-to-Quality (CTQ) features

· Notes for coatings, finish, hardness, or special processes

· Assembly references or mating component information

Callout: Our team will review everything and confirm readiness before machining.

After You Approve the FAI

Once the first article is approved:

· Full production begins

· The CNC program, tooling, and fixtures are locked in

· All subsequent parts follow the validated process

· Future design changes may trigger a partial or full re-FAI

Callout: By performing FAI, manufacturers and customers gain confidence, traceability, and peace of mind before committing to full production.

Summary

FAI is more than inspection—it is the foundation of consistent, high-precision CNC machining quality. It verifies that your CNC-machined part is correct, consistent, and production-ready before manufacturing ramps up. Our engineering team is available to help determine whether your project needs FAI, and to guide you through the process.

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

3 min readPublished Dec 09 2025

3 min readPublished Dec 09 2025

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.