Introduction of Automotive Trends

In the era of rapid technological advancement, consumer expectations for automotive and motorcycle performance have never been higher. Vehicle enthusiasts now demand not only improved performance metrics but also bespoke aesthetics and personalized driving experiences. Custom manufacturing responds to these demands by allowing manufacturers to produce parts in small batches, adapt designs quickly, and incorporate unique specifications that standard mass production cannot offer.

A prime example of this trend is found in the design and production of velocity stacks. Originally developed to optimize the airflow into engine intake systems, velocity stacks are now being engineered using custom manufacturing techniques to maximize their aerodynamic efficiency. When tailored to the exact requirements of an engine or airbox, these components can significantly enhance engine responsiveness and power output, thereby improving overall vehicle performance.

The Evolution of Custom Manufacturing

From Mass Production to Personalized Engineering

Traditionally, automotive and motorcycle parts were produced using mass production methods, which prioritized volume and consistency over customization. However, the dynamic nature of modern consumer demands has pushed manufacturers to seek out alternatives that can deliver both high quality and personalized features. Custom manufacturing provides that flexibility by allowing for the rapid iteration of designs, low-volume production runs, and the incorporation of advanced digital prototyping techniques.

Digital Prototyping and Virtual Testing

A key driver behind the shift toward custom manufacturing is the advent of digital prototyping. Digital prototyping allows designers and engineers to create virtual models of a component and simulate its performance under real-world conditions before any physical prototype is made. This approach not only speeds up the design process but also reduces the overall development cost by minimizing the need for numerous physical prototypes.

Velocity Stacks: A Case Study in Custom Manufacturing

What Are Velocity Stacks?

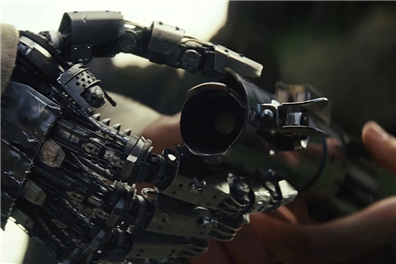

Velocity stacks are specially designed components integrated into the intake system of internal combustion engines. Their primary function is to direct and smooth the airflow into the engine’s cylinders, ensuring a more precise air–fuel mixture that enhances combustion efficiency. In the context of performance vehicles, optimized velocity stacks can lead to improvements in both torque and horsepower without compromising low-end response.

The Role of Custom Manufacturing in Velocity Stack Development

Custom manufacturing techniques, such as CNC machining and 3D printing, allow for the rapid creation and testing of multiple design iterations. This flexibility is crucial for components like velocity stacks, where even minor variations in geometry can have significant effects on performance. By leveraging digital prototyping tools, engineers can model various design scenarios and simulate their impact on airflow dynamics.

Advantages of Custom Manufacturing for Velocity Stacks

Custom manufacturing offers several distinct advantages when it comes to producing components like velocity stacks:

1. Precision and Accuracy Advanced CNC machining and 3D printing technologies enable the production of parts with tight tolerances. For velocity stacks, this means that every dimension—from inlet diameter to stack length—can be controlled with high precision, ensuring optimal airflow and performance.

2. Rapid Iteration and Prototyping Digital prototyping tools allow engineers to quickly design, test, and refine velocity stack geometries. The ability to iterate rapidly means that performance improvements can be identified and implemented much faster than traditional manufacturing methods would allow.

3. Customization and Adaptability Each engine design is unique, and a one-size-fits-all velocity stack may not provide the best performance for every application. Custom manufacturing enables the production of parts that are tailor-made for specific engines, taking into account factors such as displacement, cylinder layout, and intended performance characteristics.

4. Reduced Material Waste and Cost Efficiency Techniques such as additive manufacturing (3D printing) produce components layer by layer, minimizing waste compared to traditional subtractive methods. This efficiency not only reduces material costs but also shortens lead times, making it economically viable to produce custom parts in lower volumes.

5. Enhanced Performance and Driving Experience Ultimately, the goal of customizing velocity stacks is to enhance the driving experience. By optimizing the airflow into the engine, these components contribute to smoother power delivery, improved acceleration, and better overall performance. This translates directly into a more responsive and enjoyable driving experience for the end user.

Broader Implications of Custom Manufacturing in Automotive and Motorcycle Services

Elevating Design Flexibility

One of the most significant advantages of custom manufacturing is the increased design flexibility it affords. In the automotive and motorcycle industries, where performance and aesthetics are critical, this flexibility is invaluable. Custom manufacturing allows engineers to break free from the limitations of mass production and explore innovative designs that better meet customer needs.

Meeting Unique Consumer Demands

Today's consumers demand products that reflect their individuality. In the world of motorcycles and high-performance vehicles, customization is more than just a luxury—it's a statement of personal style and performance preference. Custom manufacturing meets this need by offering personalized product services that allow customers to specify everything from component geometry to surface finishes.

Accelerating Innovation and Product Development

Custom manufacturing plays a critical role in accelerating the innovation cycle. By reducing the time and cost associated with traditional manufacturing processes, companies can bring new ideas to market faster. Rapid prototyping and digital simulation allow engineers to test a wide range of design alternatives quickly, ensuring that only the best ideas make it to production.

Enhancing Quality and Consistency

Quality control is paramount in automotive and motorcycle manufacturing, where even minor defects can lead to significant performance issues or safety concerns. Custom manufacturing processes are often more controlled and adaptable than mass production lines, enabling higher quality and consistency across each batch of components.

Integrating Advanced Technologies

The fusion of custom manufacturing with digital technologies such as artificial intelligence (AI) and predictive analytics is transforming the automotive landscape. Companies like Czinger are already demonstrating how 3D printing combined with AI-driven design can revolutionize sports car production, setting new records on the track and reducing material usage dramatically.

In the realm of custom manufacturing, AI can help optimize component designs by analyzing vast amounts of performance data and suggesting improvements. For velocity stacks, this might involve using AI to simulate airflow patterns and predict how different geometries will affect engine performance. By integrating these advanced tools, manufacturers can continuously refine their designs, resulting in parts that not only meet but exceed performance expectations.

Promoting Sustainable Manufacturing

Sustainability is increasingly becoming a key consideration in manufacturing. Custom manufacturing methods, particularly those that utilize additive techniques, are inherently more sustainable than traditional subtractive processes. Because parts are built layer by layer, there is significantly less waste material, and energy consumption is often lower.

Impact on Driving Experience and Performance

At its core, the driving experience is defined by the relationship between the driver and the machine. For automotive and motorcycle enthusiasts, even the smallest improvements in performance can translate into a dramatically enhanced experience. Custom velocity stacks exemplify this principle. By optimizing the airflow into the engine, these components ensure that the engine “breathes” better, resulting in improved throttle response, higher power output, and smoother acceleration.

Customization for Aesthetic and Functional Appeal

Beyond performance, custom manufacturing enables unparalleled personalization in both form and function. Vehicle owners today want their rides to reflect their personality, and custom parts offer a way to achieve this. Whether it’s through unique surface finishes, bespoke design elements, or even personalized ergonomics, custom manufacturing allows for a level of detail that mass-produced parts simply cannot match.

Safety and Reliability

In addition to performance enhancements, custom manufacturing also plays a crucial role in ensuring the safety and reliability of vehicles. When components such as velocity stacks are produced using advanced digital design and precision manufacturing methods, there is less variability between parts. This consistency translates into a higher level of reliability and predictability in engine performance, which is essential for safety-critical applications.

Ecosystem of Custom Manufacturing in Automotive and Motorcycle Industries

The move toward custom manufacturing is not an isolated trend—it represents a fundamental shift in how products are designed, developed, and produced across the entire automotive and motorcycle ecosystem. Suppliers, designers, and manufacturers are increasingly working together in integrated environments where data flows seamlessly from one stage of development to the next. This collaborative innovation is facilitated by modern product lifecycle management (PLM) systems and model-based enterprise (MBE) strategies, which help synchronize the design, production, and testing of components.

Shaping the Future of Vehicle Design

Custom manufacturing is fundamentally altering the landscape of vehicle design. As manufacturers adopt advanced techniques such as predictive engineering analytics and digital twin technology, the traditional boundaries between design and production are becoming increasingly blurred. Vehicles are no longer static products but evolving systems that can be continually refined and improved over time.

Meeting the Demands of the Modern Consumer

Ultimately, custom manufacturing is driven by the evolving demands of modern consumers. Today's drivers and riders expect vehicles that are not only high-performing but also uniquely tailored to their preferences. Whether it's the precise handling of a high-performance motorcycle or the refined power delivery of a custom-tuned sports car, the demand for personalized driving experiences is at an all-time high.

Custom manufacturing meets these expectations by offering a level of personalization that goes far beyond color options or trim packages. It enables the creation of components that are custom-fit to the engine, chassis, and overall design philosophy of the vehicle—resulting in an unparalleled driving experience that is both exhilarating and uniquely personal.

Conclusion

Custom manufacturing stands at the forefront of automotive and motorcycle innovation. In a world where technology and consumer demand are in constant flux, custom manufacturing is not just a production method—it is a strategic enabler for innovation, sustainability, and excellence in the automotive and motorcycle sectors.

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

12 min readPublished Jan 20 2026

12 min readPublished Jan 20 2026

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.