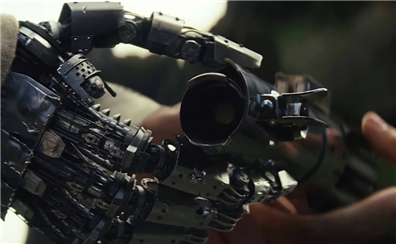

If you were to pick just one element that best represents Star Wars, the lightsaber would undoubtedly be one of the strongest candidates. Many people may be completely unaware of what Star Wars is really about, but they are also certainly no strangers to such a mysterious and powerful weapon as the lightsaber. For me, the reason for liking Star Wars is simple and pure, and it has pretty much stayed the same since I was a kid – I just think Star Wars is particularly cool. Boys may have an innate fascination with weapons and combat, plus I have a strong samurai complex, so I especially love this mysterious weapon that reveals the pride and glory of the Cold War era.

Lightsabers mean a great deal to Jedi, and each one is unique, which is why Obi-Wan often admonished young Anakin to treasure his own.

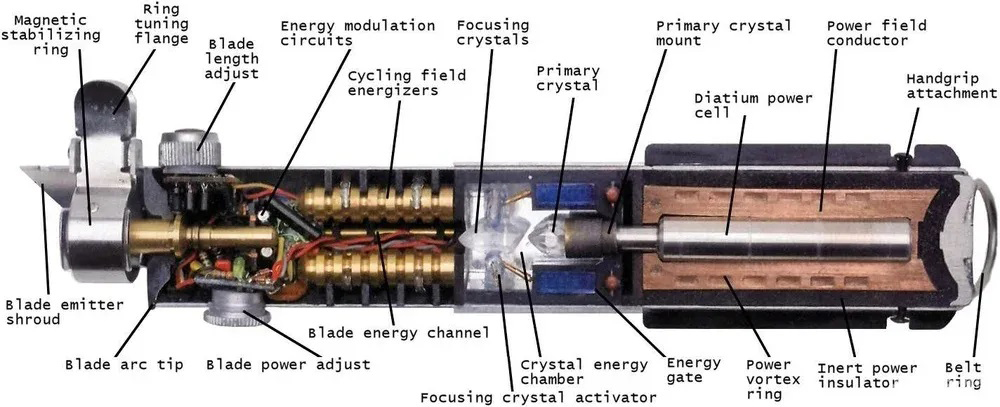

According to the setting, the blade portion of a lightsaber is a pure energy polymer, close to plasma. They are constrained into a blade shape of about one meter by a very powerful 'field', which some sources say is a magnetic field. The main function of the hilt is to provide this field so that the movement of the plasma can be confined within a certain range. The complex structure of the hilt allows the energy to form a closed circuit and take the shape of the blade, so the lightsaber hums even when not in motion. The overall structure of the lightsaber is very stable and generally consumes very little energy, except when cutting through an object or when the circuit is blocked or interfered with (when the sabers come into contact with each other).

Typically, the hilt is about 30 centimeters long and the internal base structure includes:

· Grip (the common black vertical stripe)

· Activation switch or Force switch inside (not all lightsabers can just be turned on)

· Safety lock (the lightsaber automatically shuts off when you let go)

· Emission Array (made of energy crystals that provide the plasma formed by the blade)

· Focus Crystal (converges energy, also related to the color of the blade)

· Secondary Crystals (not required)

· Focusing lens set (is a convergence of energy from crystals)

· Energy cell (supplies energy to the closed system)

· Energy gates (control the power output)

· Energy Transportation Pipes

· Blade Regulator (controls the power of the blade as well as its length)

· Energy charging port (charges the energy cells)

· Circulating field energizer

· Other accessories (blade regulator, belt loop, etc.)

However, as a CNC machining workshop, we are more exposed to the manufacturing of lightsaber hilts, with all the various design requirements, post-processing requirements, dimensional specifications, and so on. In movie settings, the key to a lightsaber is the right crystal; while in real life, a good lightsaber, of course, needs a hilt that feels, looks, and is designed perfectly.

· Customized Lightsaber Hilt Design: Our one-stop shop offers customers a unique opportunity to create their own custom light saber hilt design, allowing them to express their creativity and imagination.

· High Quality CNC Machined Parts: We utilize our CNC machining services to produce precision, accurate parts made from a variety of materials including aluminum, stainless steel, and copper, ensuring a high level of quality and durability.

· Rapid Prototyping and Milling Services: Our rapid prototyping and milling services allow customers to quickly produce and test their designs, reducing time to market and minimizing costs.

· Micromachining and Finishing Options: We offer micromachining capabilities and a variety of finishing options, including anodizing, black coating and plating, to enhance the appearance and performance of our products.

· Customization and OEM Services: We cater to individual customers and offer customization services to meet specific requirements, making it the ideal solution for enthusiasts and hobbyists, such as you, looking for a unique lightsaber hilt.Our lightsaber hilts, choose 6 series aluminum alloy material, the hilt design is divided into 12 combinations of parts, step by step processing, the method contains both turning and milling. When processing is completed, according to the customized demand for post-processing, including cleaning, deburring, sandblasting, anodising , polishing and so on. Meanwhile, for the light key, we select high transparency acrylic material, carry out through turning and milling, and process it strictly according to surface roughness of 0.8um Ra, which fully guarantees the light transmittance of the product.

Before processing, as a general rule, we will strictly match the suitable materials according to the customer's order and drawing requirements, and obtain the corresponding material certificates, combined with the process, tolerance, and post-processing requirements, processing and disassembling of the order, and step by step to complete the production.

For example, we directly adopt CNC machining centers to process the light saber parts that are suitable for machining centers. The advantages of machining center production are:

· CNC machining center has the ability of high precision machining. It adopts a digital control system, which can realize high-precision machining and ensure the requirements of dimensional accuracy and surface quality of machined parts. The structure of the machine tool has high rigidity and thermal stability, and measures have been taken to minimize errors. Positioning accuracy is generally up to 0.01mm, repeat positioning accuracy of 0.005mm. with the error can also be compensated by the CNC device, so CNC machine tools can achieve high machining accuracy.

· CNC machining center is characterized by high production efficiency. It is equipped with automatic tool change, automatic clamping, automatic measurement and other automation functions, which can realize continuous, high-speed machining and significantly improve production efficiency. CNC machine tools can effectively save maneuvering time, rapid movement to shorten the time of empty travel, a wide range of feed volume, can effectively choose a reasonable cutting amount. In addition, a clamping to complete multi-process machining, eliminating the need for multiple changes in the type of work, the conversion between processes, parts installation and adjustment time is short, thus further improving production efficiency.

· CNC machining center is very comprehensive. It can realize a variety of machining processes such as milling, boring, drilling, tapping and cutting threads, and is suitable for the machining of workpieces of various complex shapes. This multifunctional feature enables CNC machining centers to meet the machining needs of different fields, thus improving their adaptability and flexibility.

· CNC machining center also offers the advantage of cost savings. By controlling the machining process through programming, CNC machining centers can respond to the machining needs of different workpieces, thus reducing production costs. In addition, the centralization of the process allows for a reduction in the amount of work-in-process and lower tooling costs, further reducing production costs.

As for the lightsaber parts which are suitable for lathe production, we use lathe to process them. Lathe machining is a technique that involves machining raw materials into a desired shape by rotating the workpiece and removing the material using a tool. The advantages of lathe production are:

· Accuracy: CNC lathes can perform precise measurements and eliminate human error using CAD or CAM files. Whether it's a prototype or the completion of an entire production cycle, experts can use cutting-edge machinery to provide incredibly high accuracy. Because the machines used are programmed, every cut is precise. In other words, the last piece in a production run is the same as the first.

· Flexibility: CNC lathes come in a variety of sizes to meet the flexibility of your application. Adjustments are fairly easy because the tasks on this machine are pre-programmed. Operators can complete your component by making the necessary programming adjustments to your CAM program, or even build something completely different. So, if you need many unique parts, you can rely on the same precision CNC machining services company.

· Safety: Manufacturing companies follow strict safety regulations to ensure complete safety. Since the lathe is automatic, less labor is required as the operator is only there to monitor the machine. Similarly, the body of the lathe is fully or semi-enclosed with guards to avoid flying particles from the processed material and reduce injuries to the staff.

· Faster results: There is less potential for error when performing tasks programmed to be performed on a CNC lathe or turning center. As a result, this machine can produce faster without sacrificing the quality of the final output. Finally, you can receive the necessary components faster than with other options.

Of course, many parts are required to be turned and milled for processing, so we usually select the process according to the final product requirements, first lathe processing, and then in the CNC machining center processing, and then to achieve the product design requirements.

We are committed to continually improving and optimizing our capabilities in all custom processing from prototype to production and the corresponding quality control processes. We track and analyze every step of the manufacturing process to minimize part-to-part variation and ensure consistent, reliable quality every time each part is machined. With consistent quality control from part to part and product to project, we pay attention to detail, solve problems, research new materials and processes, invest in technology, build and maintain a dedicated CNC machining and manufacturing team, hence to ensure that all parts are manufactured correctly and delivered on time with best services.

We are capable of supporting your entire development cycle:

· Rapid prototyping: Quickly test shapes, fits, and functions

· Low-batch production: For pre-production validation and specialized procedures

· On-demand and continuous production: Consistent quality and reliable delivery times

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

8 min readPublished Jan 10 2026

8 min readPublished Jan 10 2026

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.