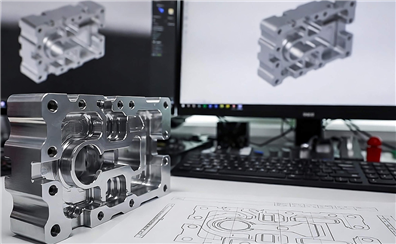

CNC machining has become the backbone of modern manufacturing, renowned for its precision, repeatability, and versatility. From aerospace components that demand extreme tolerances to customized medical implants and high-performance automotive parts, CNC machining delivers uncompromising quality across sectors.

However, this precision comes at a cost. Compared to other manufacturing processes such as injection molding or sheet metal stamping, CNC machining can be expensive, particularly for low-volume production. Tool wear, setup times, material waste, energy use, and labor all contribute to costs that can quickly escalate if not managed strategically.

In high-stakes industries like aerospace, automotive, and medical device manufacturing, controlling machining costs is not just a financial concern but a competitive necessity. Companies that optimize their machining operations without compromising quality gain a significant edge in terms of lead time, pricing, and responsiveness to market demands.

Key Factors Affecting CNC Machining Costs

Strategically managing CNC machining costs begins with understanding the variables that drive them. These factors influence pricing at every stage—from quoting to final inspection—and vary significantly based on industry, part requirements, and shop capabilities.

Material Selection & Machinability

Material choice impacts costs in two major ways:

· Raw material price: Titanium, Inconel, and certain high-performance plastics like PEEK are significantly more expensive than aluminum or mild steel.

· Machinability: Some materials are easier and faster to cut, reducing tool wear and machine time.

| Material | Cost Category | Relative Machinability (%) |

|---|---|---|

| Aluminum 6061 | Low | 90–95% |

| Mild Steel (1018) | Moderate | 80–85% |

| Stainless Steel 304 | Moderate to High | 45–50% |

| Titanium Grade 5 | High | 25–30% |

| Inconel 718 | Very High | < 20% |

Key Insight: Selecting a more machinable material can reduce total part cost by 30–50%, even if raw material costs are similar.

Part Complexity & Geometry

Part design directly affects toolpaths, cycle times, and fixturing. Key complexity drivers include:

· Deep cavities: Require long-reach tools, slow feed rates, and multiple step-downs.

· Thin walls: Risk deformation and may need slower cuts.

· Undercuts: Require specialized tools or multi-axis machining.

· Organic/freeform shapes: Demand 5-axis setups and advanced CAM programming.

Best Practice: Simplify geometry where possible, avoid sharp internal corners, and design with standard tooling in mind.

Tolerances & Surface Finishes

Tighter tolerances and fine surface finishes exponentially increase machining time and cost:

| Tolerance Level | Cost Category | Impact on Cost |

|---|---|---|

| ±0.010″ (0.25 mm) | General machining | Low |

| ±0.005″ (0.13 mm) | Precision parts | Medium |

| ±0.001″ (0.025 mm) | Aerospace/Medical | High |

| < ±0.0005″ (0.013 mm) | Critical fits | Very High |

Surface finish costs follow a similar pattern:

| Surface Finish (Ra µm) | Finish Type | Additional Cost |

|---|---|---|

| 3.2 µm | Milled | Baseline |

| 1.6 µm | Smooth | +10–20% |

| 0.8 µm | Fine | +25–40% |

| ≤0.4 µm | Polished | +50–100% (may require secondary ops) |

Tip: Apply strict tolerances and finishes only to functional features—relax the rest to cut costs.

Summary Table: Cost Impact of Key Factors

| Factor | High-Cost Scenario | Relative Machinability (%) |

|---|---|---|

| Material | Titanium | Use aluminum or high-performance polymers |

| Geometry | Deep pockets, undercuts | Simplify design, DFM review |

| Tolerances | ±0.001″ or tighter | Tolerance stack-up analysis |

| Volume | <10 parts | Batch similar jobs |

| Labor | Long setups, rework | CAM automation, standard work |

Proven Strategies to Reduce CNC Machining Costs

Reducing CNC machining costs isn’t about cutting corners—it’s about making smarter, more efficient decisions across design, programming, tooling, and operations. Below are proven strategies rooted in real-world manufacturing and lean engineering practices.

Design & Material Optimization

Design decisions impact up to 70% of production cost. DFM simplifies part features to reduce machining time and complexity:

· Avoid deep cavities: Limit depth-to-diameter ratios to reduce deflection and tool wear.

· Eliminate sharp internal corners: Use internal radii ≥3 mm to allow standard end mills.

· Unify hole sizes: Use standard drill diameters to avoid frequent tool changes.

· Minimize tight tolerances: Apply only where functionally necessary.Material Substitution

Switching to more machinable materials (e.g., aluminum instead of titanium) can reduce tool wear by 50% and cut cycle times by 30–60%, provided mechanical properties meet design requirements.

| Original Material | Cost-Effective Substitute | Use Case |

|---|---|---|

| Titanium | Aluminum 7075 | Aerospace brackets |

| Stainless Steel 316 | Mild steel + plating | Enclosures |

| PEEK | Acetal (Delrin) | Medical jigs |

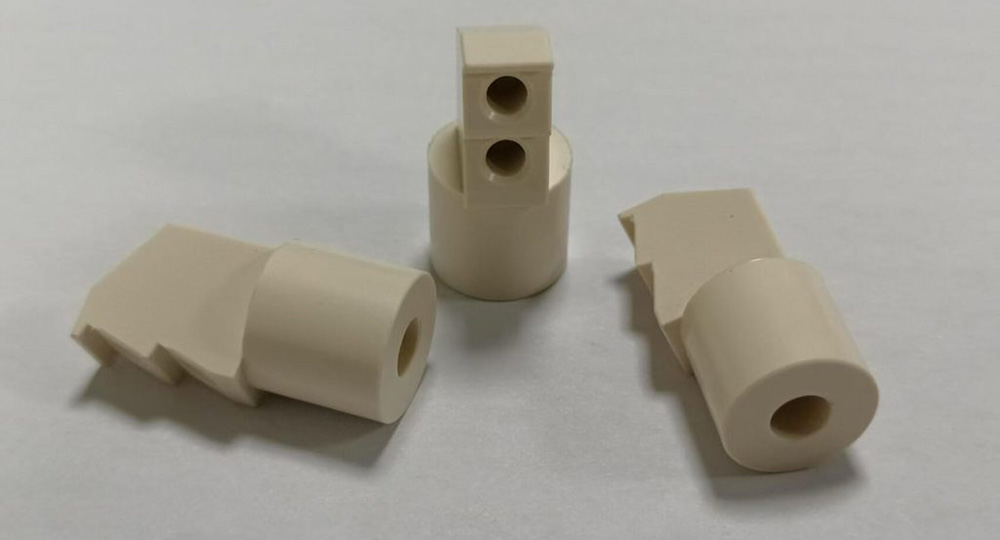

Modular and Hybrid Design

Break complex parts into simpler subcomponents. Benefits include:

· Parallel machining

· Easier inspection

· Less scrap risk

Summary Table: Strategic Cost-Saving Levers

| Area | Strategy | Estimated Impact |

|---|---|---|

| Design | DFM principles, modular parts | 20–40% cost savings |

| CAM | HEM, adaptive toolpaths | 15–60% faster cycle time |

| Tooling | Tool presetters, smart feeds/speeds | 10–30% less downtime |

| Labor | Automation, cross-training | 20–50% labor reduction |

| Operations | Lean workflows, maintenance | 10–25% increase in OEE |

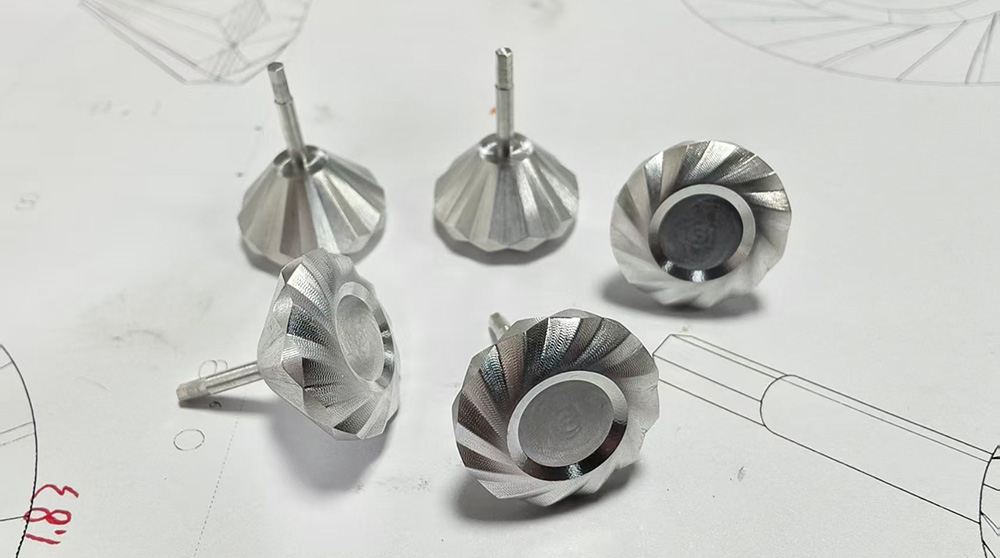

Case Studies: Real-World Cost Savings

To illustrate how strategic cost management techniques play out in practice, this section examines real-world CNC machining case studies from aerospace, automotive, and medical sectors. These examples showcase how companies applied design optimization, CAM innovation, and automation to significantly lower their manufacturing costs.

Case Study 1: Aerospace Bracket Redesign Cuts Costs by 42%

Company: Tier-1 Aerospace Supplier

Part: High-strength aluminum structural bracket

Original Problems:

· Machined from 7075-T6 aluminum billet

· Tight tolerances (±0.001″) throughout

· Undercuts requiring 5-axis machining

· Machining time: 2.5 hours per part

Optimization Techniques:

· Applied DFM review

· Redesigned bracket with open pockets and reduced undercuts

· Tolerances relaxed to ±0.005″ on non-critical features

· Switched from 5-axis to 3-axis machining with custom fixture

Results:

| Metric | Before | After | Change |

|---|---|---|---|

| Machining time | 2.5 hrs | 1.4 hrs | ↓ 44% |

| Unit cost | $380 | $220 | ↓ 42% |

| Scrap rate | 8% | <2% | ↓ 75% |

Conclusion: Smart design adjustments and tolerance rationalization enabled massive cost and time savings without compromising structural integrity.

Case Study 2: CAM Optimization Yields 50% Faster Cycle Times in Automotive Housings

Company: Automotive EV drivetrain manufacturer

Part: Precision aluminum motor housing

Challenges:

· Long cycle times (~90 minutes) due to complex internal geometry

· High tool wear and frequent tool changes

· Occasional tool breakage in deep pockets

Solution:

· Reprogrammed roughing operations using Adaptive Clearing (HEM) toolpaths

· Implemented toolpath rest machining to reduce air cutting

· Standardized tool libraries and feeds/speeds across shifts

Results:

| Metric | Before | After | Change |

|---|---|---|---|

| Cycle time | 90 min | 45 min | ↓ 50% |

| Tool cost/part | $9.50 | $4.20 | ↓ 56% |

| Production volume/day | 48 | 96 | ↑ 100% |

Conclusion: CAM software upgrades and modern toolpath strategies had a dramatic impact on productivity and tool cost, with zero capital investment.

Case Study 3: Automation Enables Lights-Out Medical Component Production

Company: Medical Device Contract Manufacturer

Part: Titanium spinal implant (multi-pass, multi-tool operation)

Initial Constraints:

· Manual loading/unloading

· Night shift required 2 operators

· Frequent scrap due to misalignment

Enhancements:

· Installed automated pallet changer system

· Deployed robotic arm for part loading

· Integrated in-machine probing and tool breakage detection

Impact:

| Metric | Before | After | Change |

|---|---|---|---|

| Labor cost/unit | $11.75 | $5.60 | ↓ 52% |

| Daily output | 240 units | 420 units | ↑ 75% |

| First-pass yield | 91% | 99.5% | ↑ 9.3% |

Conclusion: Combining robotic automation with smart probing delivered significant gains in throughput, quality, and cost per unit—critical in a tightly regulated industry.

Key Takeaways from Case Studies

| Strategy | Sector | Primary Benefit |

|---|---|---|

| DFM + Fixture redesign | Aerospace | Reduced machining time |

| Adaptive CAM strategies | Automotive | Faster cycles, lower tool cost |

| Robotics + Probing | Medical | Labor cost savings, quality boost |

| Modular fabrication | Heavy equipment | Annual cost savings via redesign |

Conclusion: Building a Cost-Efficient Workflow

Strategic cost management in CNC machining is no longer a luxury—it is a competitive imperative. As global supply chains tighten and precision requirements increase, manufacturers must leverage every opportunity to streamline operations, minimize waste, and maximize value.

Actionable Next Steps

To build a sustainable cost-efficient workflow:

· Review components for DFM.

· Eliminate unnecessary tight tolerances and undercuts.

· Use standard hole sizes, radii, and features.

· Explore modular or hybrid part designs to simplify machining.

· Choose cost-effective MaterialsCost efficiency is not about spending less—it's about spending smarter. By aligning design, engineering, and operations under a strategic cost management framework, together, we can unlock new levels of productivity, profitability, and competitiveness in an increasingly demanding manufacturing landscape.

+86 15338350382

+86 15338350382

English

English Spanish

Spanish French

French Russian

Russian Italian

Italian German

German Japanese

Japanese

6 min readPublished Jan 04 2026

6 min readPublished Jan 04 2026

sophia@alcrocn.com

sophia@alcrocn.com

+86 15338350382

+86 15338350382

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.

6th North Street, Xiagang Community, Chang'an Town, Dongguan City, Guangdong Province, China.